Efficient oil reservoir analysis relies on understanding the behavior of reservoir fluids under varying conditions. This is where viscometer measurement improves the process, offering a window into the viscosity and flow properties of these fluids. Cambridge Viscosity’s ViscoLab PVT+ viscometer equips reservoir engineers with the ability to assess the fluid’s viscosity, even under extreme pressure and temperature conditions, mirroring real-world reservoir scenarios.

Viscometer Measurement: A Glimpse into Reservoir Fluid Dynamics

Sep 26, 2023 11:41:02 AM / by Admin posted in viscosity control, oil reservoir viscosity, viscosity management, ViscoLab PVT+

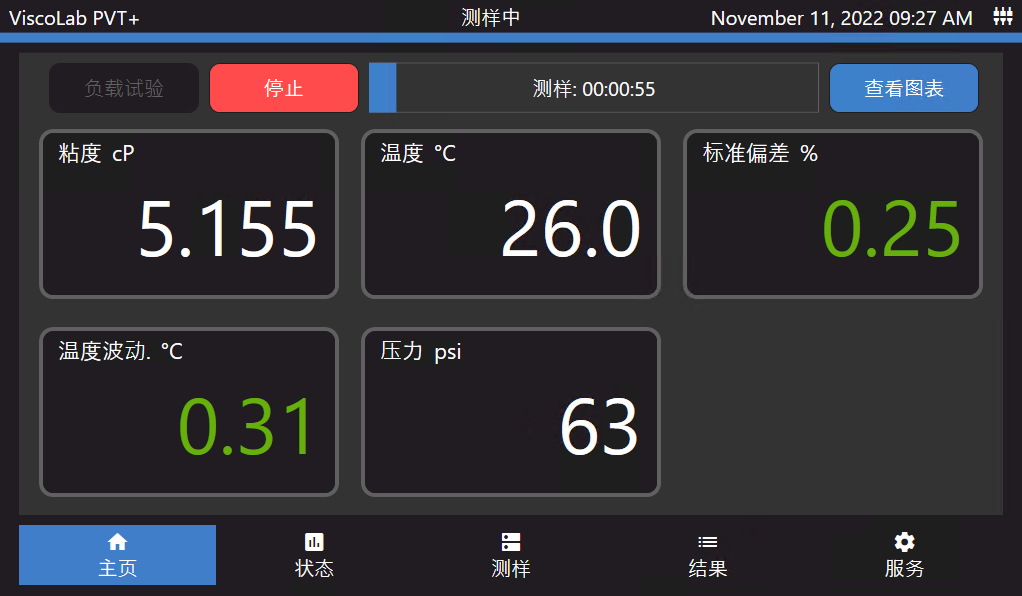

CVI Adds Language Support to Its ViscoLab PVT+ Viscometer

Nov 15, 2022 10:33:00 AM / by Patrick Riley posted in international, viscosity control, viscosity management, ViscoLab PVT+

Ease of use for our customers is important, and we know that having our products available in the local languages makes it easier for customers to do their jobs. That’s why we’re excited to announce that we are incorporating three new languages within our new ViscoLab PVT+ viscometer. These languages are 1) Mandarin (Chinese), 2) Spanish, and 3) Portuguese.

CVI Attends PAC’s Europe, Middle East, & Africa Distributor Meeting

Oct 6, 2022 12:53:23 PM / by Patrick Riley posted in viscometer meeting, viscosity management, viscometer, viscosity, customer service

Our distributors are the secret weapon to our success. They’re knowledgeable, support a local presence around the world, and help us deliver the most value to our customers. That’s why we were excited to attend PAC’s Process Solutions Europe, Middle East, & Africa Distributor Meeting. Process Solutions, made up of PAC’s Process Analytics Group, Cambridge Viscosity, Phase Analytics, and Advanced Sensors, specializes in advanced analytical instruments for online processes.

Vanko & CVI Partner to Provide Viscometers to a Municipal WWT Plant

May 11, 2022 2:54:26 PM / by Patrick Riley posted in viscosity measuring solution, viscosity control, viscosity management, wastewater treatment

CVI’s new ViscoLab PVT+ supports informed, intelligent decision making

Mar 24, 2022 9:05:35 AM / by Patrick Riley posted in viscosity measuring solution, viscosity management, ViscoLab PVT+

Designed to deliver high levels of accuracy and reliability, CVI’s new PVT+ offers unmatched viscosity, pressure and temperature capabilities

Employee Highlight: René de Martin

Mar 2, 2022 9:52:59 AM / by Patrick Riley posted in viscosity measuring solution, viscosity management, customer service

For this week’s blog, we’re excited to highlight our new Area Sales Manager for Europe, Middle East, and Africa. The role is in PAC’s Process Analytics group, of which CVI is a part.

Employee Highlight - Connor Douglas

Feb 9, 2022 9:52:21 AM / by Patrick Riley posted in viscosity measuring solution, viscosity control, viscosity management, customer service

We’re pleased to share that Connor Douglas was promoted to the position of Head of Products for PAC’s Process Analytics group. Connor’s responsibilities will include product vision, roadmap, strategy, and execution for Cambridge Viscosity, Advanced Sensors, and PAC Process Analyzers.

Using a Viscometer to Control Coating in Pen Needle Manufacturing

Nov 17, 2021 7:49:54 AM / by Patrick Riley posted in viscosity control, coating viscosity, viscosity management, 372 sensor

We recently asked some of our global reps to interview customers in key industries, so we can get a deeper understanding of some of the issues customers are facing right now. Jerzy Janota, Technical Director at Industa, recently talked to a customer in a medical device production company based in Europe. The customer recently installed a ViscoPro 2100 with the SPC 372 sensor.

Using the ViscoLab PVT+ to Measure Non-Newtonian Fluids

Nov 3, 2021 10:21:54 AM / by Patrick Riley posted in oil viscosity, viscosity measuring solution, viscosity control, viscosity management, ViscoLab PVT+

Getting rheological data that mimics subsurface conditions above 15,000 PSI and/or 200°C can be a challenge with conventional rheometers. The Cambridge Viscosity ViscoLab PVT+ offers a solution to this challenge by providing shear rates with the viscosity measurement and a shear sweep function to collect data at multiple shear rates within a single test. The PVT+ has options for measuring at pressures in excess of 30,000 PSI (or higher upon request), temperatures to 315°C, and viscosities as low as 0.02cP, which is well beyond the capability of commercially available, HPHT rheometers.

When the Supply Chain Gets Crazy

Oct 21, 2021 3:09:42 PM / by Patrick Riley posted in viscosity management, supply chain

If there’s been any lesson to be learned over the past two years, it’s that our global supply chain is fragile. From The Great Toilet Paper Shortage of 2020, to the Great Car Shortage of 2021, we learned that it doesn’t take much for the grocery store shelves and the car lots to turn into vast deserts of emptiness.

Using ViscoPro 2100 Viscometers for a Lubrication Test Apparatus

Sep 15, 2021 2:49:22 PM / by Patrick Riley posted in viscosity measuring solution, viscosity control, viscosity management, refrigerant viscosity, ViscoPro 2100

Since 2006, CPI Fluid Engineering, a division of the Lubrizol Corporation (a Berkshire Hathaway company), has used Cambridge Viscosity ViscoPro 1600 viscometers as an important research tool in their testing. Recently, they built a new testing apparatus with expanded measurement capabilities.

Upgrade Your Existing PVT Viscometer

Sep 8, 2021 1:46:29 PM / by Patrick Riley posted in PVT, viscosity measuring solution, viscosity control, viscosity management, ViscoLab PVT+

How long has your PVT viscometer been in use? If your viscometer is more than 10 years old, we should talk. Even if your legacy instrument is operating at acceptable levels, the latest technology offers a wealth of benefits that can deliver a fast ROI, and make a positive impact on your laboratory. Why should you upgrade?

How to Remove a Series 500 Piston

Jun 29, 2021 7:45:00 AM / by Admin posted in 571 sensor, viscosity control, viscosity management, lens viscosity, in-line viscometers, 500 series viscometer

Recently, a few of our team members created a video to help a customer with a minor issue they were having. We thought that if one customer might have the issue, another might, also, so we uploaded the video, How to Remove a Cambridge Viscosity 500 Series Viscometer Piston, in case it could help other customers.

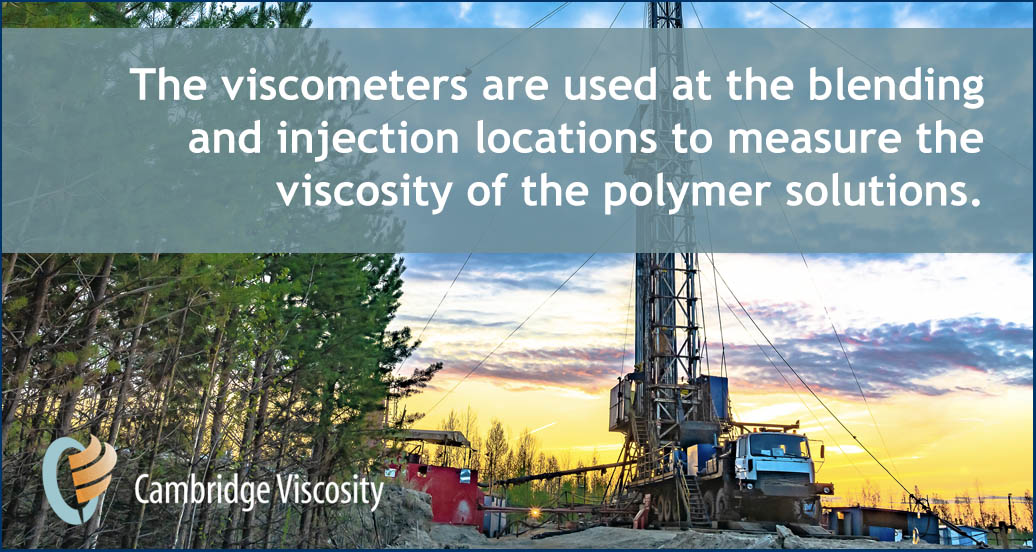

CVI's ViscoPro 2100 helps increase oil recovery by as much as 20%

Jun 23, 2021 11:10:41 AM / by Patrick Riley posted in reservoir fluid, oil reservoir viscosity, viscosity management, in-line viscometers, ViscoPro 2100

In mature, oil-producing reservoirs, conditions like natural fissions in the reservoir rock or resistance from heavier or more viscous oils require enhanced oil recovery (EOR) injection techniques. Polymer flooding is one EOR technique that is widely used because it can significantly improve oil recovery over conventional flooding. It uses polymer solutions in an aqueous medium to increase oil recovery by reducing the water-to-oil mobility ratio. Managing the viscosity of the EOR polymers at the well head supports efficient oil production, while helping to reduce the amount of EOR polymer needed.

An interview with CVI Rep Suzhou TAIEN about the Compressor Industry

Jun 17, 2021 12:12:25 PM / by Patrick Riley posted in viscosity measuring solution, viscosity control, gas compressor, viscosity management, compressor viscosity

Did you know we have a global representative network that supports Cambridge viscometers all over the world? We decided to reach out to a few of them to get their thoughts on the compressor industry. The first rep we talked to is Suzhou TAIEN, who is responsible for viscometer sales and support in China.