Continuous Measurement of Temperature and Viscosity

Viscosity Range: 0.2 to 20,000 centipoise (cP)

Repeatability: 0.5% of Reading

Accuracy: 1.0%

Maximum Temperature: 375°C (707°F)

Pressure Range: 1,000 psi (70.3 bar)

Wetted Parts: 316L or Hastily

.jpg)

| Specifications | |

| Viscosity | 0.2 to 20,000 centipoise (cP) |

| Piston Ranges | 0.2-2cP, 0.25-5cP, 0.5-10cP, 1-20cP, 2.5-50cP, 5-100cP, 10-200cP, 25-500cP, 50-1,000cP, 100-2,000cP, 250-5,000cP, 500-10,000cP, 1,000-20,000cP |

| Viscosity Accuracy | ± 1.0% |

| Repeatability | 0.5% of Reading |

| Temperature Sensor | 4 wire internal Platinum RTD |

| Wetted Materials | 316L and Hastelloy |

| Maximum Particle Size | 25-360 microns (Range Dependent) |

| Max Ambient Temperature | 375°C (707°F) |

| Max Operating Pressure | 1,000 psi (70.3 bar) |

| Standard Cable Length | 15 feet (4.5 meters) |

| Power |

Requires VISCOpro electronics |

• Approved for Class 1, Div. 1, Group C & D

• Approved for EEx d IIC T2, -20°C<Tamb<190°C

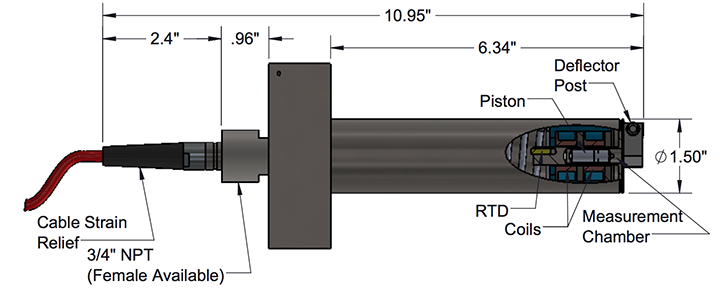

Cambridge Viscosity’s Model SPC/L392 in-line viscometer sensor provides continuous measurement of temperature and viscosity. The sensor can be used with our ViscoPro electronics to meet any viscosity management application.

Our patented technology is based on a simple and reliable electromagnetic concept. Two coils pull a piston back and forth within a constantly refreshed sample of process fluid. Proprietary circuitry analyzes the piston’s travel time to measure absolute viscosity. A built-in temperature detector (RTD) senses the actual temperature in the measurement chamber.

Measurements can be made in any of the 13 different 20:1 viscosity ranges that are available covering a span of 0.2 to 20,000 cP.

The sensor is designed with a four-bolt stainless-steel SAE Code 61 flange and is easily installed in pipelines ranging from 2” and larger in size. Custom tees are available. The back of the sensor is fitted with a 3/4”-18 NPT fitting to accommodate electrical conduit. The sensor’s self-cleaning feature helps to make it maintenance free in many applications.

*NOTE: ALL ATEX SENSORS ARE SPL ONLY (L = hard wired, C = connector).

Features:

Known for innovation in viscosity measurement and control, Cambridge Viscosity specializes in the industry's most accurate, reliable, and easy-to-use viscometers for research laboratories and process environments.

Cambridge Viscosity, Inc.

50 Redfield St, Suite 204

Boston, MA 02122 USA

781 393-6500

Email: Sales@CambridgeViscosity.com