Improving Bottom Line Profits with Real-Time Viscosity Monitoring of Asphalts

Improving Bottom Line Profits with Real-Time Viscosity Monitoring of Asphalts

Seen in Petro Industry News

Temperature-Compensated Viscosity: Key to Coating Consistency

Temperature-Compensated Viscosity: Key to Coating Consistency

Seen in Paint & Coatings Industry

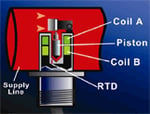

Lubricant Viscosity Control for Gas Compressors

Lubricant Viscosity Control for Gas Compressors

Picture courtesy Petro Industry News

When oil is struck, Cambridge Viscosity helps Schlumberger-DBR Technology analyze it

When oil is struck, Cambridge Viscosity helps Schlumberger-DBR Technology analyze it

Real-time viscosity monitoring offers key to bunker quality verification.

Real-time viscosity monitoring offers key to bunker quality verification.

"In-line Viscosity Monitoring Vs Sampling," from World Bunkering Magazine

In-line viscometers are the "cruise control" of heavy fuel oil viscosity management.

In-line viscometers are the "cruise control" of heavy fuel oil viscosity management.

"Cambridge Enhances Fuel Viscosity Controller," from Diesel & Gas Turbine Worldwide Magazine

EMDiesel uses Cambridge Viscosity sensors on their most advanced production engines.

EMDiesel uses Cambridge Viscosity sensors on their most advanced production engines.

The rotogravure revolution continues! Cambridge Viscosity offers features that converters are now demanding.

The rotogravure revolution continues! Cambridge Viscosity offers features that converters are now demanding.

Real-time on-engine oil viscosity tracks fuel dilution, additive breakdown and oxidation.

Real-time on-engine oil viscosity tracks fuel dilution, additive breakdown and oxidation.

Viscosity control yields high ROI for coil coaters.

Viscosity control yields high ROI for coil coaters.

Bunker Quality: In-Line Viscosity

Bunker Quality: In-Line Viscosity

Monitoring vs. Sampling

Known for innovation in viscosity measurement and control, Cambridge Viscosity specializes in the industry's most accurate, reliable, and easy-to-use viscometers for research laboratories and process environments.

Cambridge Viscosity, Inc.

50 Redfield St, Suite 204

Boston, MA 02122 USA

781 393-6500

Email: Sales@CambridgeViscosity.com