Efficient oil reservoir analysis relies on understanding the behavior of reservoir fluids under varying conditions. This is where viscometer measurement improves the process, offering a window into the viscosity and flow properties of these fluids. Cambridge Viscosity’s ViscoLab PVT+ viscometer equips reservoir engineers with the ability to assess the fluid’s viscosity, even under extreme pressure and temperature conditions, mirroring real-world reservoir scenarios.

Viscometer Measurement: A Glimpse into Reservoir Fluid Dynamics

Sep 26, 2023 11:41:02 AM / by Admin posted in viscosity control, oil reservoir viscosity, viscosity management, ViscoLab PVT+

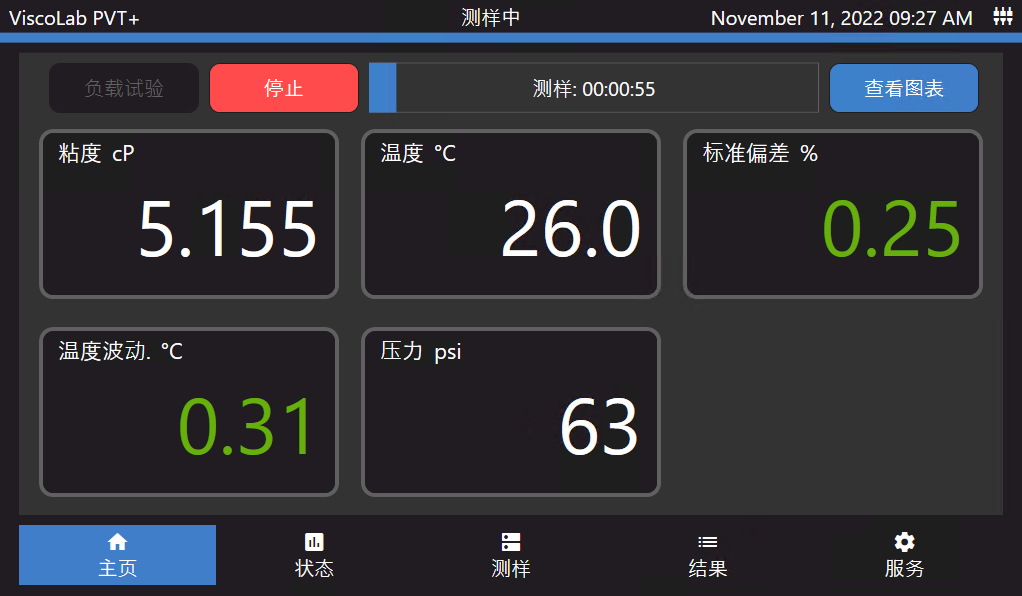

CVI Adds Language Support to Its ViscoLab PVT+ Viscometer

Nov 15, 2022 10:33:00 AM / by Patrick Riley posted in international, viscosity control, viscosity management, ViscoLab PVT+

Ease of use for our customers is important, and we know that having our products available in the local languages makes it easier for customers to do their jobs. That’s why we’re excited to announce that we are incorporating three new languages within our new ViscoLab PVT+ viscometer. These languages are 1) Mandarin (Chinese), 2) Spanish, and 3) Portuguese.

Vanko & CVI Partner to Provide Viscometers to a Municipal WWT Plant

May 11, 2022 2:54:26 PM / by Patrick Riley posted in viscosity measuring solution, viscosity control, viscosity management, wastewater treatment

Photos from CVI's Latin & South American Distributor Meeting

May 4, 2022 9:51:40 PM / by Patrick Riley posted in viscosity measuring solution, viscosity control, viscometer support

Cambridge Viscosity had a great time in Vancouver, BC, Canada meeting with our Latin American channel partners at our first in-person distributor meeting since 2019! It was so good to see our colleagues from SICA, Supertec, Pensalab, Cecoltec, Melvyn Becerra & Cia., and Jose Jalill Haas Representaciones face-to-face, after more than two years of virtual meetings.

Employee Spotlight: Jon Lilley

Apr 13, 2022 10:58:40 AM / by Patrick Riley posted in viscosity control, customer service

In this week’s blog, we’re highlighting one of our Boston-based employees, Jon Lilley. If you’ve ever had the chance to talk to Jon, you’ll know that he’s a quiet guy, so when he agreed to let us spotlight him, we jumped at the chance.

Employee Highlight - Connor Douglas

Feb 9, 2022 9:52:21 AM / by Patrick Riley posted in viscosity measuring solution, viscosity control, viscosity management, customer service

We’re pleased to share that Connor Douglas was promoted to the position of Head of Products for PAC’s Process Analytics group. Connor’s responsibilities will include product vision, roadmap, strategy, and execution for Cambridge Viscosity, Advanced Sensors, and PAC Process Analyzers.

Using a Viscometer to Control Coating in Pen Needle Manufacturing

Nov 17, 2021 7:49:54 AM / by Patrick Riley posted in viscosity control, coating viscosity, viscosity management, 372 sensor

We recently asked some of our global reps to interview customers in key industries, so we can get a deeper understanding of some of the issues customers are facing right now. Jerzy Janota, Technical Director at Industa, recently talked to a customer in a medical device production company based in Europe. The customer recently installed a ViscoPro 2100 with the SPC 372 sensor.

Viscosity Control Improves the Medical Device Manufacturing Process

Nov 10, 2021 2:01:49 PM / by Patrick Riley posted in viscosity measuring solution, viscosity control, coating viscosity, medical devices

Why Coatings are Important in the Medical Device Industry

Medical professionals are not thinking about the coatings on their instruments when they’re using them – they’re focused whether the instrument is doing its job correctly as it’s being used. However, if the coating on a medical device is off-spec, or too thin or thick, or not displaying the required characteristics, the device may not perform as intended, and the effects can range from a minor distortion of characteristics to unacceptable in-vivo interactions. Quality control in medical device manufacturing is taken very seriously. Off-spec and inconsistent coatings lead to waste, which can be costly.

Using the ViscoLab PVT+ to Measure Non-Newtonian Fluids

Nov 3, 2021 10:21:54 AM / by Patrick Riley posted in oil viscosity, viscosity measuring solution, viscosity control, viscosity management, ViscoLab PVT+

Getting rheological data that mimics subsurface conditions above 15,000 PSI and/or 200°C can be a challenge with conventional rheometers. The Cambridge Viscosity ViscoLab PVT+ offers a solution to this challenge by providing shear rates with the viscosity measurement and a shear sweep function to collect data at multiple shear rates within a single test. The PVT+ has options for measuring at pressures in excess of 30,000 PSI (or higher upon request), temperatures to 315°C, and viscosities as low as 0.02cP, which is well beyond the capability of commercially available, HPHT rheometers.

Capturing Carbon in Fossil-Fueled Power Plants

Sep 29, 2021 4:13:31 PM / by Patrick Riley posted in viscosity measuring solution, viscosity control, ViscoPro 2100, process viscometer

Because atmospheric carbon dioxide levels are higher today than they have been at any point in the last 800,000 years1, there’s a need to develop improved ways to manage carbon capture. There are many different methods for carbon capture, but most tend to be energy intensive, water intensive, and expensive. The most common solvent is monoethanolamine (MEA), which has a significant water percentage (30% amine and 70% water). According to research from National Energy Technology Laboratory (NETL), by 2030, the addition of carbon capture technology could boost water consumption by fossil power plants by 80 percent.

Using ViscoPro 2100 Viscometers for a Lubrication Test Apparatus

Sep 15, 2021 2:49:22 PM / by Patrick Riley posted in viscosity measuring solution, viscosity control, viscosity management, refrigerant viscosity, ViscoPro 2100

Since 2006, CPI Fluid Engineering, a division of the Lubrizol Corporation (a Berkshire Hathaway company), has used Cambridge Viscosity ViscoPro 1600 viscometers as an important research tool in their testing. Recently, they built a new testing apparatus with expanded measurement capabilities.

Upgrade Your Existing PVT Viscometer

Sep 8, 2021 1:46:29 PM / by Patrick Riley posted in PVT, viscosity measuring solution, viscosity control, viscosity management, ViscoLab PVT+

How long has your PVT viscometer been in use? If your viscometer is more than 10 years old, we should talk. Even if your legacy instrument is operating at acceptable levels, the latest technology offers a wealth of benefits that can deliver a fast ROI, and make a positive impact on your laboratory. Why should you upgrade?

Offshore Technology Conference: 2021 Image Gallery

Aug 19, 2021 2:18:51 PM / by Patrick Riley posted in viscosity control, ViscoPro 2100, viscometer calibration, ViscoLab PVT+

This week, the Cambridge Viscosity team has been in Houston, Texas for the Offshore Technology Conference (OTC). OTC is the largest oil and gas conference in the world. In normal years, attendance is about 59,000 industry professionals. Due to Covid, OTC was canceled in 2020. This year, the event was scaled back in size in consideration of the safety of attendees. Despite being scaled back a bit, the conference has been great. We've have great conversations with industry professionals, who, like us, have been excited to travel for the first time in over a year.

Cambridge Viscosity set to launch new ViscoLab PVT+ at OTC in August

Jul 22, 2021 9:56:54 AM / by Patrick Riley posted in high temperature viscometer, viscosity control, ViscoLab PVT+

In 2019, when things were still normal and we took tradeshows and conferences for granted as a typical part of the comings and goings of business, 60 thousand people from over 100 countries converged on Houston to attend the Offshore Technology Conference (OTC) for its 50th anniversary. The theme for that year, “Going the Distance,” highlighted innovations in technology in digitalization. I find it ironic that less than a year later, “going the distance” for many of us was a commute to our dining rooms where a make-shift office was set up during quarantine.

Regulatory Uncertainty Drives Demand for Explosion-Proof Technologies

Jul 14, 2021 1:30:16 PM / by Patrick Riley posted in explosion-proof, viscosity measuring solution, viscosity control, gas compressor, compressor viscosity, refrigerant viscosity

Air conditioning systems use refrigerants to do the job of cooling an indoor space. These refrigerants, in the form of hydrochlorofluorocarbons (HCFCs), potentially contribute to climate change, and are currently being phased out of use in the United States. The phaseout approach, which was initially started in 2010, gives manufacturers time to develop ozone-friendly refrigerants as an alternative.