We’re always thrilled when long-time industry professionals join us as new employees at PAC. This is definitely the case with Karl Kuklenz, who was recently hired in the role of Product Manager, Process Analytics.

Employee Highlight: Kark Kuklenz

Sep 23, 2022 7:50:29 AM / by Patrick Riley posted in viscometer support, viscosity, process viscometer, customer service

Evaluating the ViscoPro 2100: A Customer Service Story

Feb 3, 2022 11:54:45 AM / by Patrick Riley posted in ViscoPro 2100, process viscometer, customer service

There are a lot of ways to demonstrate customer service. A quick response to an email, access to a knowledgeable human quickly when a customer has a question, a good support program, well-written technical manuals. The list goes on. For Cambridge Viscosity’s sales manager, Rob Segnatelli, customer service occasionally takes the form of running samples for new customers using the ViscoPro 2100 that he keeps on his desk.

Capturing Carbon in Fossil-Fueled Power Plants

Sep 29, 2021 4:13:31 PM / by Patrick Riley posted in viscosity measuring solution, viscosity control, ViscoPro 2100, process viscometer

Because atmospheric carbon dioxide levels are higher today than they have been at any point in the last 800,000 years1, there’s a need to develop improved ways to manage carbon capture. There are many different methods for carbon capture, but most tend to be energy intensive, water intensive, and expensive. The most common solvent is monoethanolamine (MEA), which has a significant water percentage (30% amine and 70% water). According to research from National Energy Technology Laboratory (NETL), by 2030, the addition of carbon capture technology could boost water consumption by fossil power plants by 80 percent.

Finding the right balance of lubricants and refrigerants

May 11, 2021 8:08:00 AM / by Patrick Riley posted in 571 sensor, viscosity management, compressor viscosity, process viscometer

When it comes to air conditioning and compressor systems, achieving ideal operating efficiency is about balance. Too much lubricant means the compressor or cooling system won’t cool properly, and too much refrigerant increases bearing wear and reduces the system life. Thicker oil lubricates better, but it also means there is an increase in drag, and more power is needed to rotate the compressor. Manufacturers must consider all these variables when manufacturers designing their equipment. Each new design requires significant testing to ensure performance and energy efficiency.

CVI's Viscometers Support the Manufacture of Safety Eyewear

Jan 26, 2021 12:35:09 PM / by Patrick Riley posted in viscosity control, eyewear viscosity, Coating, process viscometer

Safety eyewear has never been more important than right now. In an industry that was already growing at a rate of 4% CAGR, with a projection to reach $3B by 2025, the COVID pandemic created a massive surge in demand for safety eyewear in 2020.

Lessons Learned: Viscosity Control for Converters

Jan 20, 2021 10:08:35 AM / by Patrick Riley posted in viscosity control, coating viscosity, viscosity management, in-line viscometers, process viscometer

Almost two months ago, while those of us in the United States were enjoying our Thanksgiving holiday, our associates in Italy were holding a webinar on viscosity measurement in pressroom converters. This event inspired a series of material discussing the coating application, including last week’s blog highlighting factors that influence viscosity measurement in the pressroom converter application.

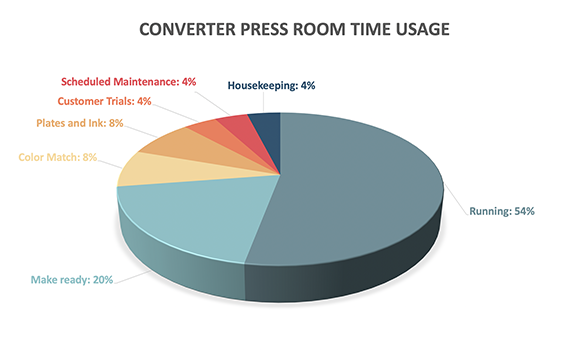

Optimize your converter press room time usage

Jan 14, 2021 3:13:22 PM / by Patrick Riley posted in viscosity measuring solution, coating viscosity, viscosity management, process viscometer

Today's blog discusses pressroom converters. (And we're offering a free white paper on the topic — see the link at the bottom of this post.)

Ensuring Quality of Wire Coatings with Viscometry

Dec 16, 2020 9:28:49 AM / by Patrick Riley posted in viscosity control, viscosity management, Coating, in-line viscometers, ViscoPro 2100, process viscometer

Measuring viscosity in asphalt leads to a reduction in energy usage

Nov 17, 2020 2:59:47 PM / by Patrick Riley posted in viscosity control, asphalt viscosity, ViscoPro 2100, process viscometer

November in New England, where Cambridge Viscosity is headquartered, is the time of year when our leaves finish falling and the weather turns cold. Soon, it will be snowy and frigid in Massachusetts. (Who are we kidding – we had our first snowfall in October this year!) Inspired by the chill in the air, we thought we’d talk about some of the challenges of measuring viscosity in colder atmospheric conditions, where ambient temperatures fall below 50 °F for part of the year

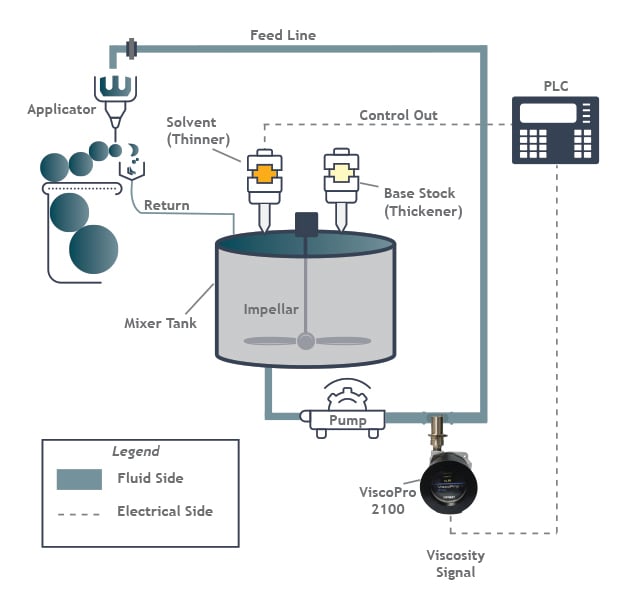

Eliminate Paint Problems Before They Happen

Oct 7, 2020 9:46:49 AM / by Patrick Riley posted in coating viscosity, viscometer, process viscometer, paint viscosity

In an auto industry that is more competitive than ever, any technology that enhances quality is well worth considering – especially when the benefits far outweigh any costs.

Preventative maintenance of my process viscometer

Aug 26, 2020 11:19:26 AM / by Patrick Riley posted in monitor viscosity, in-line viscometers, viscometer, process viscometer

Cambridge Viscosity process viscometers are known for robust operation and reliability in viscosity measurements. Performing scheduled Preventative Maintenance (PM) on your Cambridge Viscosity viscometer is vital to system operation, longevity, and verification. Cambridge Viscosity recommends performing PM on your viscometer on an annual basis as defined in our Operational Manual. PM can be performed at more frequent intervals if deemed necessary due to internal QA or other departmental policies.