In this week’s blog, we’re highlighting one of our Boston-based employees, Jon Lilley. If you’ve ever had the chance to talk to Jon, you’ll know that he’s a quiet guy, so when he agreed to let us spotlight him, we jumped at the chance.

Employee Spotlight: Jon Lilley

Apr 13, 2022 10:58:40 AM / by Patrick Riley posted in viscosity control, customer service

CVI’s new ViscoLab PVT+ supports informed, intelligent decision making

Mar 24, 2022 9:05:35 AM / by Patrick Riley posted in viscosity measuring solution, viscosity management, ViscoLab PVT+

Designed to deliver high levels of accuracy and reliability, CVI’s new PVT+ offers unmatched viscosity, pressure and temperature capabilities

The requirements for viscosity measurement are changing across all industries. PVT labs, which are capital-intense projects, tend to be expensive to set up and run. In order to survive in an uncertain market, PVT labs are cutting costs and reducing manpower. This means they need to automate processes to increase efficiencies, reduce cycle time to maximize productivity, and develop software models using historical data to predict results. The ViscoLab PVT+ is Cambridge Viscosity's answer to those changes. Based on the current and changing demands of the oil and gas industry, Cambridge Viscosity invested significantly in the next generation of its PVT viscometer. The new ViscoLab PVT+:

Employee Highlight: René de Martin

Mar 2, 2022 9:52:59 AM / by Patrick Riley posted in viscosity measuring solution, viscosity management, customer service

For this week’s blog, we’re excited to highlight our new Area Sales Manager for Europe, Middle East, and Africa. The role is in PAC’s Process Analytics group, of which CVI is a part.

Employee Highlight - Connor Douglas

Feb 9, 2022 9:52:21 AM / by Patrick Riley posted in viscosity measuring solution, viscosity control, viscosity management, customer service

We’re pleased to share that Connor Douglas was promoted to the position of Head of Products for PAC’s Process Analytics group. Connor’s responsibilities will include product vision, roadmap, strategy, and execution for Cambridge Viscosity, Advanced Sensors, and PAC Process Analyzers.

Evaluating the ViscoPro 2100: A Customer Service Story

Feb 3, 2022 11:54:45 AM / by Patrick Riley posted in ViscoPro 2100, process viscometer, customer service

There are a lot of ways to demonstrate customer service. A quick response to an email, access to a knowledgeable human quickly when a customer has a question, a good support program, well-written technical manuals. The list goes on. For Cambridge Viscosity’s sales manager, Rob Segnatelli, customer service occasionally takes the form of running samples for new customers using the ViscoPro 2100 that he keeps on his desk.

Employee Spotlight: Meet Kevin John, Viscometer Service and Support

Jan 27, 2022 2:26:43 PM / by Patrick Riley posted in process viscometers, service, lab viscometer, viscosity, on-site service

Customer service and support is really important to us at Cambridge Viscosity. It’s important that our customers get the best installation, startup, calibration, troubleshooting, and training we can offer. We feel like we do customer service really well, and one of the reasons for that is Kevin John.

An interview with the ViscoLab PVT+ product development team

Jan 12, 2022 8:17:50 AM / by Patrick Riley posted in high temperature viscometer, viscosity measuring solution, high pressure viscometer, temperature compensated viscosity, ViscoLab PVT+

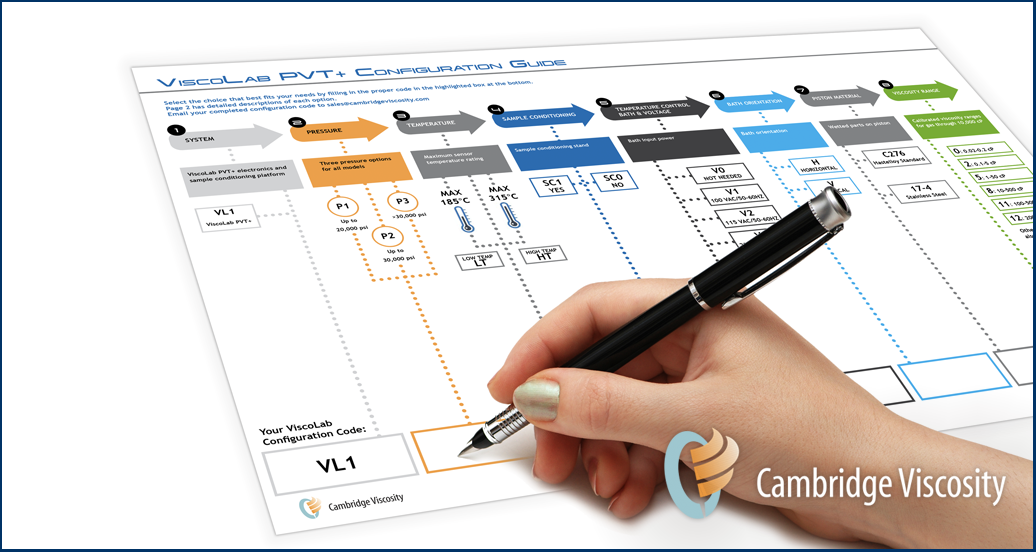

ViscoLab PVT+ Configuration Guide Now Available

Dec 15, 2021 3:14:48 PM / by Patrick Riley

Cambridge Viscosity has a wide range of customers. Some of them know as much about viscometers as we do, and know exactly what they want. Others might be making their first viscometer purchase and don’t have a clear idea of what they need. In either case, we try to make the purchasing process as easy as possible. For years, we’ve been creating configuration guides that walk our customers through the specification process.

Using a Viscometer to Control Coating in Pen Needle Manufacturing

Nov 17, 2021 7:49:54 AM / by Patrick Riley posted in viscosity control, coating viscosity, viscosity management, 372 sensor

We recently asked some of our global reps to interview customers in key industries, so we can get a deeper understanding of some of the issues customers are facing right now. Jerzy Janota, Technical Director at Industa, recently talked to a customer in a medical device production company based in Europe. The customer recently installed a ViscoPro 2100 with the SPC 372 sensor.

Viscosity Control Improves the Medical Device Manufacturing Process

Nov 10, 2021 2:01:49 PM / by Patrick Riley posted in viscosity measuring solution, viscosity control, coating viscosity, medical devices

Why Coatings are Important in the Medical Device Industry

Medical professionals are not thinking about the coatings on their instruments when they’re using them – they’re focused whether the instrument is doing its job correctly as it’s being used. However, if the coating on a medical device is off-spec, or too thin or thick, or not displaying the required characteristics, the device may not perform as intended, and the effects can range from a minor distortion of characteristics to unacceptable in-vivo interactions. Quality control in medical device manufacturing is taken very seriously. Off-spec and inconsistent coatings lead to waste, which can be costly.

Using the ViscoLab PVT+ to Measure Non-Newtonian Fluids

Nov 3, 2021 10:21:54 AM / by Patrick Riley posted in oil viscosity, viscosity measuring solution, viscosity control, viscosity management, ViscoLab PVT+

Getting rheological data that mimics subsurface conditions above 15,000 PSI and/or 200°C can be a challenge with conventional rheometers. The Cambridge Viscosity ViscoLab PVT+ offers a solution to this challenge by providing shear rates with the viscosity measurement and a shear sweep function to collect data at multiple shear rates within a single test. The PVT+ has options for measuring at pressures in excess of 30,000 PSI (or higher upon request), temperatures to 315°C, and viscosities as low as 0.02cP, which is well beyond the capability of commercially available, HPHT rheometers.

How to spend less time managing coating thickness

Oct 27, 2021 9:46:17 AM / by Patrick Riley posted in coating viscosity, optical coating viscosity, temperature compensated viscosity

Over the last few decades, optical coating technologies have been becoming progressively more complex. Optics control light in a manner to make a product useful, and coatings do a great job in that by modifying how light is transmitted, absorbed, and reflected to make the product more efficient and functional. Optical coatings are made up of several thin film layers, creating an interference effect. How the coating works depends on variables like the number of layers, the thickness of each coating layer, and the different refractive indices of each layer.

When the Supply Chain Gets Crazy

Oct 21, 2021 3:09:42 PM / by Patrick Riley posted in viscosity management, supply chain

If there’s been any lesson to be learned over the past two years, it’s that our global supply chain is fragile. From The Great Toilet Paper Shortage of 2020, to the Great Car Shortage of 2021, we learned that it doesn’t take much for the grocery store shelves and the car lots to turn into vast deserts of emptiness.

Our Viscometers Just Keep Going and Going …

Oct 7, 2021 8:27:20 AM / by Patrick Riley posted in PVT, high pressure viscometer, lab viscometer, viscometer

We talk a lot about the accuracy and reliability of our viscometers, and about how they can often run for years without maintenance. It doesn’t matter which viscometer you have – it’s going to be a solid instrument. The reason for this is in the design. The sensors only have a single moving part – the piston – which is electromagnetically driven through fluid in a small measurement chamber. With fluid in the measurement chamber, two coils move the piston back and forth at a constant force. Because the piston is in constant motion, it continuously scrubs the sampling area. The viscometers are self-cleaning, and they don’t require frequent recalibration.