Over the last few decades, optical coating technologies have been becoming progressively more complex. Optics control light in a manner to make a product useful, and coatings do a great job in that by modifying how light is transmitted, absorbed, and reflected to make the product more efficient and functional. Optical coatings are made up of several thin film layers, creating an interference effect. How the coating works depends on variables like the number of layers, the thickness of each coating layer, and the different refractive indices of each layer.

Over the last few decades, optical coating technologies have been becoming progressively more complex. Optics control light in a manner to make a product useful, and coatings do a great job in that by modifying how light is transmitted, absorbed, and reflected to make the product more efficient and functional. Optical coatings are made up of several thin film layers, creating an interference effect. How the coating works depends on variables like the number of layers, the thickness of each coating layer, and the different refractive indices of each layer.

The demand for optical products is significant. Mobile electronics, solar cells, 3D devices, biomedical applications, laser applications, photonic devices, eyewear … the list goes on. When demand is high, manufacturers need to ramp their production and maximize their product yield.

The coating of an optical product is very important, and it needs to be right. If the specs are off – if the coating layer is too thin, the product will likely fail quality control testing and end up in the scrap pile. This means yield is reduced and expensive coating is wasted. If the product is too thick, the product might not function correctly, and the over-use of coating becomes a sizable expense. Using 20% extra coating on a product run of over 1,000,000 adds up to be a significant over-spend on coating.

Optical manufacturers spend a lot of time managing coating thickness. It doesn’t matter whether the coating was dipped, sprayed, or rolled. Thickness is directly related to the amount of solids in the coating fluid. Too many solids means the coating is too thick, and not enough solids means it’s too thin. These types of quality deviations is a certain route to the scrap pile.

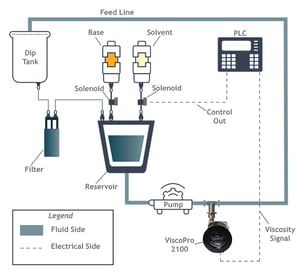

A viscosity measurement is a direct correlation of solids content. If the solids to solvent ratio changes, the viscosity will change with it. An in-line viscometer is the most direct, fastest and most accurate method of determining if the ratio is changing and provides control of material addition, so you can consistently maintain the ratio over a production run.

Cambridge Viscosity’s ViscoPro 2100 is an excellent choice when it comes to managing the viscosity of coating fluids. The VP2100 is compact, making it ideal for even low volume coating stations. It is highly accurate and repeatable for maintaining tight control over the process and itrequires no maintenance as the calibration is stable and doesn’t drift over time.

We recently published a white paper, “What Challenges are Optical Lens Manufacturers Facing in 2021?” It discusses some of the more complex issues that manufacturers are facing today, and it offers possible solutions to the industry’s most prevalent coating challenges.