There are a lot of ways to demonstrate customer service. A quick response to an email, access to a knowledgeable human quickly when a customer has a question, a good support program, well-written technical manuals. The list goes on. For Cambridge Viscosity’s sales manager, Rob Segnatelli, customer service occasionally takes the form of running samples for new customers using the ViscoPro 2100 that he keeps on his desk.

Recent Posts

Evaluating the ViscoPro 2100: A Customer Service Story

Feb 3, 2022 11:54:45 AM / by Patrick Riley posted in ViscoPro 2100, process viscometer, customer service

Employee Spotlight: Meet Kevin John, Viscometer Service and Support

Jan 27, 2022 2:26:43 PM / by Patrick Riley posted in process viscometers, service, lab viscometer, viscosity, on-site service

Customer service and support is really important to us at Cambridge Viscosity. It’s important that our customers get the best installation, startup, calibration, troubleshooting, and training we can offer. We feel like we do customer service really well, and one of the reasons for that is Kevin John.

An interview with the ViscoLab PVT+ product development team

Jan 12, 2022 8:17:50 AM / by Patrick Riley posted in high temperature viscometer, viscosity measuring solution, high pressure viscometer, temperature compensated viscosity, ViscoLab PVT+

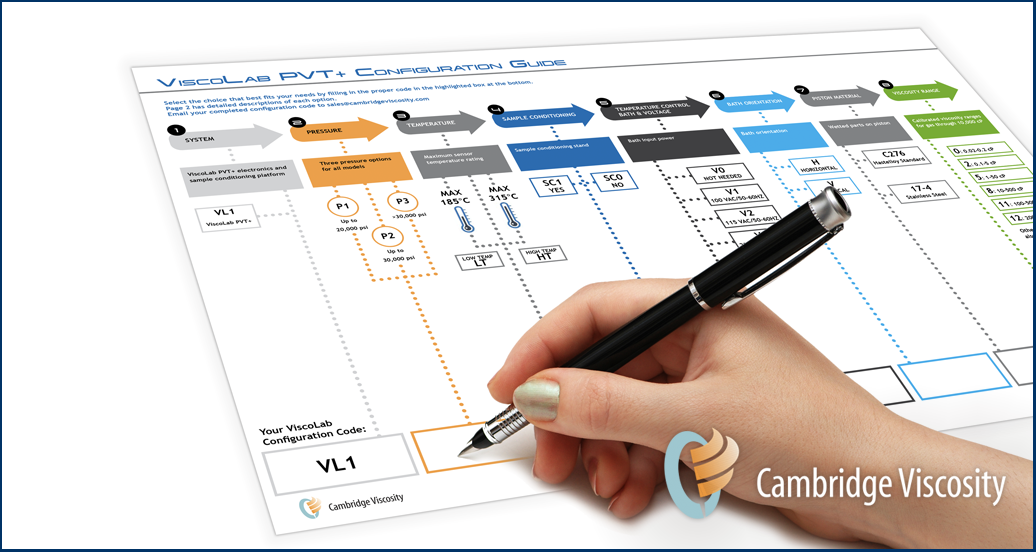

ViscoLab PVT+ Configuration Guide Now Available

Dec 15, 2021 3:14:48 PM / by Patrick Riley

Cambridge Viscosity has a wide range of customers. Some of them know as much about viscometers as we do, and know exactly what they want. Others might be making their first viscometer purchase and don’t have a clear idea of what they need. In either case, we try to make the purchasing process as easy as possible. For years, we’ve been creating configuration guides that walk our customers through the specification process.

Using a Viscometer to Control Coating in Pen Needle Manufacturing

Nov 17, 2021 7:49:54 AM / by Patrick Riley posted in viscosity control, coating viscosity, viscosity management, 372 sensor

We recently asked some of our global reps to interview customers in key industries, so we can get a deeper understanding of some of the issues customers are facing right now. Jerzy Janota, Technical Director at Industa, recently talked to a customer in a medical device production company based in Europe. The customer recently installed a ViscoPro 2100 with the SPC 372 sensor.

Viscosity Control Improves the Medical Device Manufacturing Process

Nov 10, 2021 2:01:49 PM / by Patrick Riley posted in viscosity measuring solution, viscosity control, coating viscosity, medical devices

Why Coatings are Important in the Medical Device Industry

Medical professionals are not thinking about the coatings on their instruments when they’re using them – they’re focused whether the instrument is doing its job correctly as it’s being used. However, if the coating on a medical device is off-spec, or too thin or thick, or not displaying the required characteristics, the device may not perform as intended, and the effects can range from a minor distortion of characteristics to unacceptable in-vivo interactions. Quality control in medical device manufacturing is taken very seriously. Off-spec and inconsistent coatings lead to waste, which can be costly.

Using the ViscoLab PVT+ to Measure Non-Newtonian Fluids

Nov 3, 2021 10:21:54 AM / by Patrick Riley posted in oil viscosity, viscosity measuring solution, viscosity control, viscosity management, ViscoLab PVT+

Getting rheological data that mimics subsurface conditions above 15,000 PSI and/or 200°C can be a challenge with conventional rheometers. The Cambridge Viscosity ViscoLab PVT+ offers a solution to this challenge by providing shear rates with the viscosity measurement and a shear sweep function to collect data at multiple shear rates within a single test. The PVT+ has options for measuring at pressures in excess of 30,000 PSI (or higher upon request), temperatures to 315°C, and viscosities as low as 0.02cP, which is well beyond the capability of commercially available, HPHT rheometers.

How to spend less time managing coating thickness

Oct 27, 2021 9:46:17 AM / by Patrick Riley posted in coating viscosity, optical coating viscosity, temperature compensated viscosity

Over the last few decades, optical coating technologies have been becoming progressively more complex. Optics control light in a manner to make a product useful, and coatings do a great job in that by modifying how light is transmitted, absorbed, and reflected to make the product more efficient and functional. Optical coatings are made up of several thin film layers, creating an interference effect. How the coating works depends on variables like the number of layers, the thickness of each coating layer, and the different refractive indices of each layer.

When the Supply Chain Gets Crazy

Oct 21, 2021 3:09:42 PM / by Patrick Riley posted in viscosity management, supply chain

If there’s been any lesson to be learned over the past two years, it’s that our global supply chain is fragile. From The Great Toilet Paper Shortage of 2020, to the Great Car Shortage of 2021, we learned that it doesn’t take much for the grocery store shelves and the car lots to turn into vast deserts of emptiness.

Our Viscometers Just Keep Going and Going …

Oct 7, 2021 8:27:20 AM / by Patrick Riley posted in PVT, high pressure viscometer, lab viscometer, viscometer

We talk a lot about the accuracy and reliability of our viscometers, and about how they can often run for years without maintenance. It doesn’t matter which viscometer you have – it’s going to be a solid instrument. The reason for this is in the design. The sensors only have a single moving part – the piston – which is electromagnetically driven through fluid in a small measurement chamber. With fluid in the measurement chamber, two coils move the piston back and forth at a constant force. Because the piston is in constant motion, it continuously scrubs the sampling area. The viscometers are self-cleaning, and they don’t require frequent recalibration.

Capturing Carbon in Fossil-Fueled Power Plants

Sep 29, 2021 4:13:31 PM / by Patrick Riley posted in viscosity measuring solution, viscosity control, ViscoPro 2100, process viscometer

Because atmospheric carbon dioxide levels are higher today than they have been at any point in the last 800,000 years1, there’s a need to develop improved ways to manage carbon capture. There are many different methods for carbon capture, but most tend to be energy intensive, water intensive, and expensive. The most common solvent is monoethanolamine (MEA), which has a significant water percentage (30% amine and 70% water). According to research from National Energy Technology Laboratory (NETL), by 2030, the addition of carbon capture technology could boost water consumption by fossil power plants by 80 percent.

Using ViscoPro 2100 Viscometers for a Lubrication Test Apparatus

Sep 15, 2021 2:49:22 PM / by Patrick Riley posted in viscosity measuring solution, viscosity control, viscosity management, refrigerant viscosity, ViscoPro 2100

Since 2006, CPI Fluid Engineering, a division of the Lubrizol Corporation (a Berkshire Hathaway company), has used Cambridge Viscosity ViscoPro 1600 viscometers as an important research tool in their testing. Recently, they built a new testing apparatus with expanded measurement capabilities.

Upgrade Your Existing PVT Viscometer

Sep 8, 2021 1:46:29 PM / by Patrick Riley posted in PVT, viscosity measuring solution, viscosity control, viscosity management, ViscoLab PVT+

How long has your PVT viscometer been in use? If your viscometer is more than 10 years old, we should talk. Even if your legacy instrument is operating at acceptable levels, the latest technology offers a wealth of benefits that can deliver a fast ROI, and make a positive impact on your laboratory. Why should you upgrade?

CVI ViscoLab PVT+ viscometer is designed for challenging applications

Aug 27, 2021 3:33:36 PM / by Patrick Riley posted in PVT, lube oil viscosity, high temperature viscometer, viscosity measuring solution, Exploration, high pressure viscometer

A PVT (Pressure/Viscosity/Temperature) analysis is required several oil applications. PVT measurement provides oil companies a deep understanding of a fluid’s characteristics, so they can make better, more informed decisions. Variability in oil is normal, and drillers need to be able to assess the quality of oil, as well as the best method for extraction, production, and processing of the heavy crude. PVT measurement is also used in bearing analysis, to assess lube oil under bearing conditions.

Offshore Technology Conference: 2021 Image Gallery

Aug 19, 2021 2:18:51 PM / by Patrick Riley posted in viscosity control, ViscoPro 2100, viscometer calibration, ViscoLab PVT+

This week, the Cambridge Viscosity team has been in Houston, Texas for the Offshore Technology Conference (OTC). OTC is the largest oil and gas conference in the world. In normal years, attendance is about 59,000 industry professionals. Due to Covid, OTC was canceled in 2020. This year, the event was scaled back in size in consideration of the safety of attendees. Despite being scaled back a bit, the conference has been great. We've have great conversations with industry professionals, who, like us, have been excited to travel for the first time in over a year.