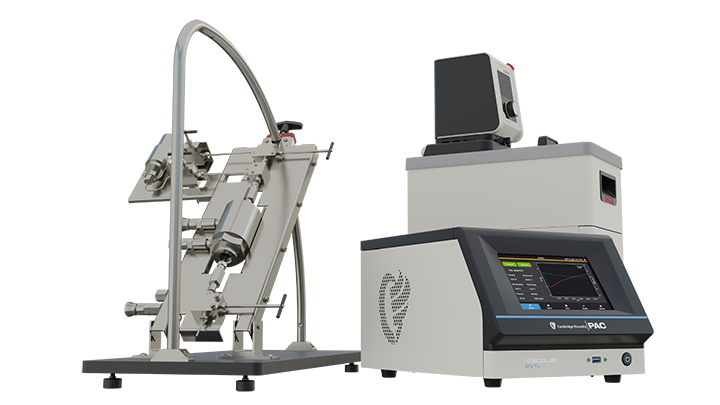

The ViscoLab PVT+ is the latest in PVT technology by Cambridge Viscosity. This small-yet-powerful viscometer features a touchscreen interface with customizable functions to ensure fast access to the right information. Traditional PVT units, which include a laptop, pressure transducer, hub, air bath, and electronics, take up valuable workspace. The ViscoLab PVT+ is designed for the needs of the laboratory. It combines the user interface, pressure transducer, hub, and electronics in a single, compact enclosure. When mobility is a requirement, the PVT+ fits on a 30”x40” cart, and can be easily transported to other areas or laboratories. Plus, it has a low torque ceiling for easy assembly or disassembly.

Recent Posts

CVI launches the ViscoLab PVT+ for Hi-Temp, Hi-Pressure Applications

Aug 12, 2021 3:37:55 PM / by Patrick Riley posted in high temperature viscometer, viscosity measuring solution, ViscoLab PVT+

Cambridge Viscosity set to launch new ViscoLab PVT+ at OTC in August

Jul 22, 2021 9:56:54 AM / by Patrick Riley posted in high temperature viscometer, viscosity control, ViscoLab PVT+

In 2019, when things were still normal and we took tradeshows and conferences for granted as a typical part of the comings and goings of business, 60 thousand people from over 100 countries converged on Houston to attend the Offshore Technology Conference (OTC) for its 50th anniversary. The theme for that year, “Going the Distance,” highlighted innovations in technology in digitalization. I find it ironic that less than a year later, “going the distance” for many of us was a commute to our dining rooms where a make-shift office was set up during quarantine.

Regulatory Uncertainty Drives Demand for Explosion-Proof Technologies

Jul 14, 2021 1:30:16 PM / by Patrick Riley posted in explosion-proof, viscosity measuring solution, viscosity control, gas compressor, compressor viscosity, refrigerant viscosity

Air conditioning systems use refrigerants to do the job of cooling an indoor space. These refrigerants, in the form of hydrochlorofluorocarbons (HCFCs), potentially contribute to climate change, and are currently being phased out of use in the United States. The phaseout approach, which was initially started in 2010, gives manufacturers time to develop ozone-friendly refrigerants as an alternative.

CVI's ViscoPro 2100 helps increase oil recovery by as much as 20%

Jun 23, 2021 11:10:41 AM / by Patrick Riley posted in reservoir fluid, oil reservoir viscosity, viscosity management, in-line viscometers, ViscoPro 2100

In mature, oil-producing reservoirs, conditions like natural fissions in the reservoir rock or resistance from heavier or more viscous oils require enhanced oil recovery (EOR) injection techniques. Polymer flooding is one EOR technique that is widely used because it can significantly improve oil recovery over conventional flooding. It uses polymer solutions in an aqueous medium to increase oil recovery by reducing the water-to-oil mobility ratio. Managing the viscosity of the EOR polymers at the well head supports efficient oil production, while helping to reduce the amount of EOR polymer needed.

An interview with CVI Rep Suzhou TAIEN about the Compressor Industry

Jun 17, 2021 12:12:25 PM / by Patrick Riley posted in viscosity measuring solution, viscosity control, gas compressor, viscosity management, compressor viscosity

Did you know we have a global representative network that supports Cambridge viscometers all over the world? We decided to reach out to a few of them to get their thoughts on the compressor industry. The first rep we talked to is Suzhou TAIEN, who is responsible for viscometer sales and support in China.

Cambridge Viscosity Attends Petro Phase 2021 Virtual Seminar

Jun 11, 2021 1:37:50 PM / by Patrick Riley

It’s been an interesting and busy week for Cambridge Viscosity. On Monday, Tuesday, and Wednesday, (June 7-9, 2021), we attended Petro Phase 2021 as a virtual seminar. The 2020 seminar was canceled last year due to COVID restrictions, so it was nice to get back to the conference circuit, albeit virtually. If you missed the live event but are interested in seeing the material, it’s available (through registration) until the end of July.

CVI’s 372 Sensor Ideal for High Pressures and Temperature Control

Jun 3, 2021 10:09:22 AM / by Patrick Riley posted in viscosity control, in-line viscometers, 372 sensor

Overview of the 501 Viscometer Sensor

May 25, 2021 1:02:21 PM / by Patrick Riley posted in 501 sensor, viscosity measuring solution

It's no secret to anyone familiar with Cambridge Viscosity that we're proud of our sensor technology. We talk a lot about our oscillating piston technology, which is based on an electromagnetic concept, where two coils move the piston back and forth magnetically at a constant force. (You can see the video showing how it works here.) The patented concept makes for a highly stable, low maintenance viscometer that maintains calibration and needs minimal service. It literally has only one moving part, and no wear points. The most convenient part is that our sensors are self-cleaning.

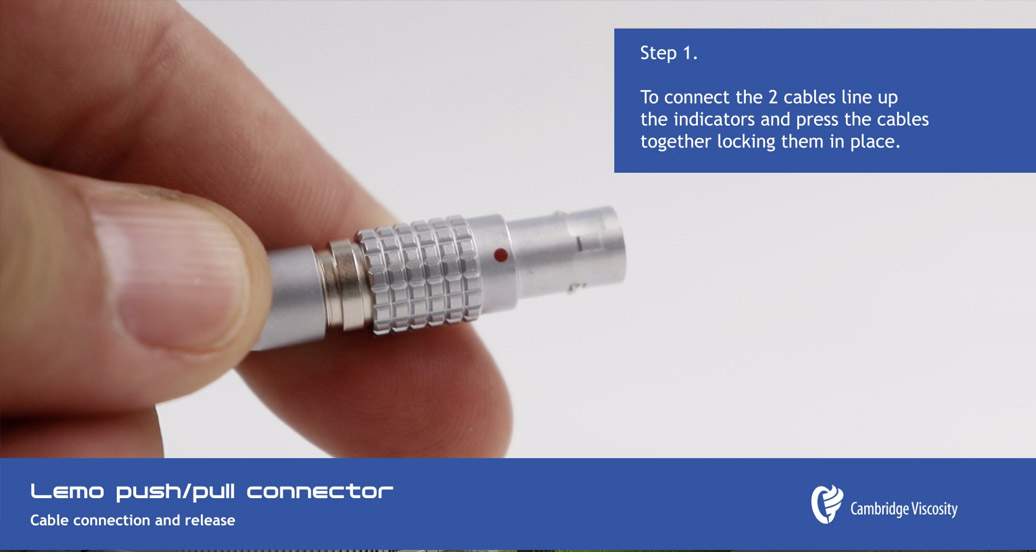

How to Connect a Lemo Push-Pull Connector

May 20, 2021 11:13:31 AM / by Patrick Riley posted in 501 sensor, viscosity measuring solution

The Cambridge Viscosity 501 viscometer sensor incorporates a Lemo push-pull connector. The Lemo connector is a push/pull style of connector that is self latching. Known to be effective, the Lemo connector is widely used across many industries. The system mates the connectors when the plug is pushed axially into the socket. To do this, line up the red indicator dots and press the cables together, which locks them into place. Once the latch is made, the connection won't release by twisting or pulling any component, other than the outer release sleeve. The connection can only be disengaged by pulling on the outer release sleeve, which allows the user to disengage the latch and withdraw the plug.

To release the cables, grab the knurled release and pull it back. Do not pull the cables apart without using the release, as this can damage both the cable and the sensor.

We've also had a few instances where end-users have twisted the connector, rather than pulled the connector to release. This can also damage the equipment. To better support our customers, we've created the videos below to demonstrate the correct way to release the Lemo connector attached to a CVI 501 Viscometer sensor.

Finding the right balance of lubricants and refrigerants

May 11, 2021 8:08:00 AM / by Patrick Riley posted in 571 sensor, viscosity management, compressor viscosity, process viscometer

When it comes to air conditioning and compressor systems, achieving ideal operating efficiency is about balance. Too much lubricant means the compressor or cooling system won’t cool properly, and too much refrigerant increases bearing wear and reduces the system life. Thicker oil lubricates better, but it also means there is an increase in drag, and more power is needed to rotate the compressor. Manufacturers must consider all these variables when manufacturers designing their equipment. Each new design requires significant testing to ensure performance and energy efficiency.

VISCOpro Used in Research to Analyze Viscosity in a Rotary Compressor

Apr 29, 2021 8:31:44 AM / by Patrick Riley posted in 501 sensor, viscosity measuring solution, viscosity control, research, compressor viscosity

When compressor manufacturers design a new compressor model, part of the process includes determining the type of refrigerant and the accompanying lubricating oil, which is necessary to reduce friction on metal parts, reduce wear on the compressor, and extend the life of the system. The company must conduct extensive testing to ensure proper energy efficiency and functionality. The lubricant has a significant impact on the performance of the compressor. Over-lubrication can impact the compressor’s ability to cool properly, but too much refrigerant will lead to more wear and a shorter compressor lifecycle.

Showing Off Our PVT Video Campaign

Apr 21, 2021 6:23:22 PM / by Patrick Riley posted in PVT, high temperature viscometer, high pressure viscometer, 440 sensor

The VISCOlab PVT is a high-pressure, high-temperature viscometer. It is no secret that we are pretty proud of it. The PVT is a great product. It has the widest temperature range, the widest pressure range, and the widest viscosity range of any viscometer on the market. When you want to achieve accurate viscosity measurement under conditions of extreme pressure and temperature, the VISCOlab PVT is your viscometer.

Configuring Your Viscometer When You Know Exactly What You Want

Apr 14, 2021 12:25:40 PM / by Patrick Riley posted in monitor viscosity, viscosity measuring solution, viscosity control, ViscoPro 2100

If there’s anything that we’ve learned in 30+ years of business, it’s that our customers are smart. Often, you’re the best in your field. You know your industry as well as you know the face looking back at you in the mirror.

Reduce blending time for a lubrication product with viscosity analysis

Apr 7, 2021 3:54:45 PM / by Patrick Riley posted in lube oil viscosity, viscosity measuring solution, blending

A refinery was interested in increasing the production of their lubrication products by reducing the time it takes to formulate the products. The facility had several blending tanks in varying sizes, which were used for blending multiple products. Their operating procedures required that they test samples from the top, middle, and bottom of the tanks to ensure the samples were homogenous. Because they didn’t know the exact blending time of the batches, their procedures required that they wait for an hour or more to be sure that full blending had occurred. This effort was time-intensive and could add 45 minutes or more to a batch. If the mixing wasn’t complete and the tests needed to be performed again, even more time would be added to the process.

CVI Offers On-Site Service Capabilities

Mar 24, 2021 9:15:13 AM / by Patrick Riley posted in in-line viscometers, on-site service

- Annual inspection

- Cleaning

- Verification of settings

- Reviewing historical data and error logs

- Calibration verification