When it comes to rotating equipment, it’s a question of when—not if—a failure will occur. Engine breakdowns, for example, are often caused when the bearings in rotating parts fail. What does this have to do with viscosity, you may be wondering. Faulty bearings can generally be traced to one of three issues: 1) Severe service conditions, 2) improper handling or installation, or 3) poor lubrication.

Recent Posts

Monitor the viscosity of lube oil to reduce failures in engines

Mar 16, 2021 9:43:04 AM / by Patrick Riley posted in lube oil viscosity, viscosity control, viscosity management, 301 sensor

White Paper: Accurate Viscosity Measurement in Extreme Conditions

Mar 9, 2021 10:39:14 AM / by Patrick Riley posted in PVT, viscosity control, Exploration, high pressure viscometer, EOR

The need for accurate and reliable viscosity measurement in high pressures and temperatures spans many applications across multiple industries. Oil exploration, enhanced oil recovery, and bearing analysis are just a few. Cambridge Viscosity has a long history of meeting these challenges. The key is in the SPL-440 sensor, which is the heart of the VISCOlab PVT. Our new white paper touches on why viscosity measurement is so important when it comes to oil extraction.

Download the White Paper: Achieving Accurate Viscosity Measurement in Conditions of Extreme Pressure and Temperature

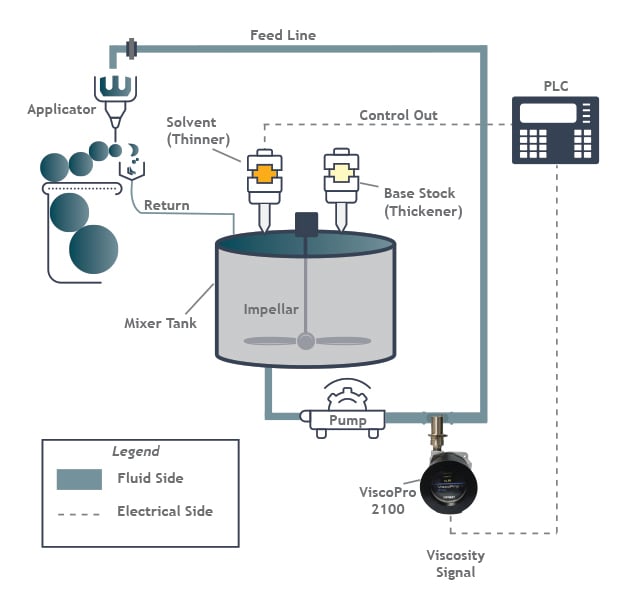

Oil condition monitoring for lube oil monitoring on screw compressors

Feb 17, 2021 11:55:02 AM / by Patrick Riley posted in viscosity control, viscosity management, compressor viscosity, in-line viscometers, ViscoPro 2100

Managing lubricant viscosity is essential to maintaining the health of a compressor in a process plant, because a single compressor failure can cost $10,000 a day or more in lost revenue. Considering it’s another $10,000 to rebuild a compressor, or more than $100,000 to replace a compressor, maintaining the health and performance of compressors is important.

Our Top 10 Favorite Questions Relating to Coatings

Feb 10, 2021 12:41:06 PM / by Patrick Riley

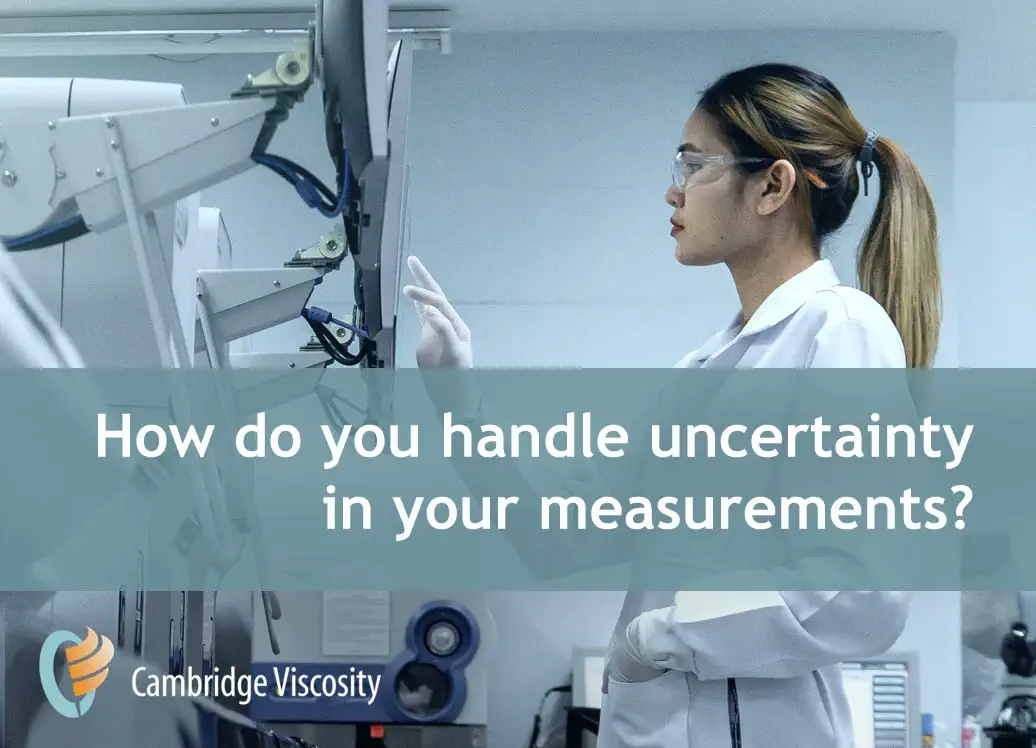

When your lab measurements are different than the in-line measurements

Feb 3, 2021 12:39:04 PM / by Patrick Riley posted in viscosity measuring solution, viscosity control, viscosity management, in-line viscometers, ViscoPro 2100, viscometer

There is always some level of uncertainty in comparing on-line viscosity measurements with laboratory measurements. When it comes to viscosity analysis, a major reason for that uncertainty – and inconsistent measurements – is because the fluids are, in fact, under different conditions.

CVI's Viscometers Support the Manufacture of Safety Eyewear

Jan 26, 2021 12:35:09 PM / by Patrick Riley posted in viscosity control, eyewear viscosity, Coating, process viscometer

Safety eyewear has never been more important than right now. In an industry that was already growing at a rate of 4% CAGR, with a projection to reach $3B by 2025, the COVID pandemic created a massive surge in demand for safety eyewear in 2020.

Lessons Learned: Viscosity Control for Converters

Jan 20, 2021 10:08:35 AM / by Patrick Riley posted in viscosity control, coating viscosity, viscosity management, in-line viscometers, process viscometer

Almost two months ago, while those of us in the United States were enjoying our Thanksgiving holiday, our associates in Italy were holding a webinar on viscosity measurement in pressroom converters. This event inspired a series of material discussing the coating application, including last week’s blog highlighting factors that influence viscosity measurement in the pressroom converter application.

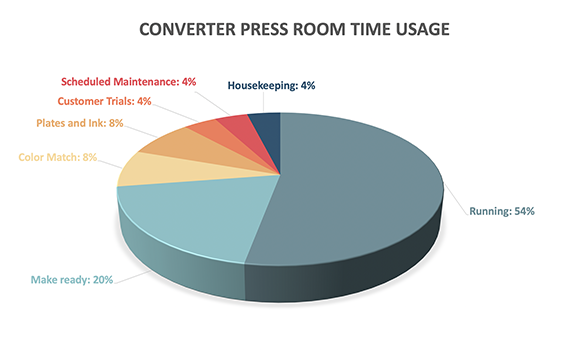

Optimize your converter press room time usage

Jan 14, 2021 3:13:22 PM / by Patrick Riley posted in viscosity measuring solution, coating viscosity, viscosity management, process viscometer

Today's blog discusses pressroom converters. (And we're offering a free white paper on the topic — see the link at the bottom of this post.)

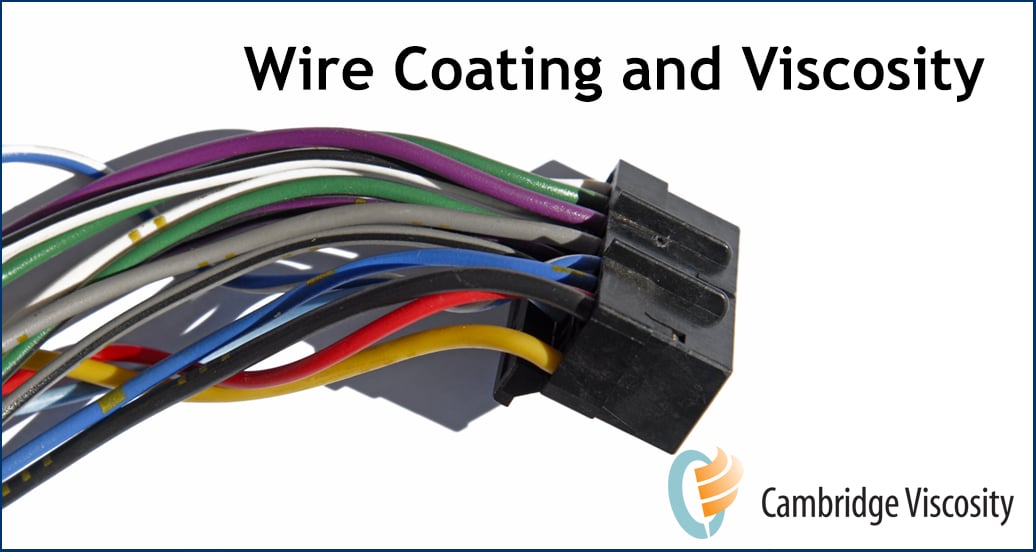

Viscosity Measurement Supports Uniform Coating for Wire Manufacturing

Jan 4, 2021 1:17:06 PM / by Patrick Riley posted in viscosity measuring solution, viscosity control, wire coating, coating viscosity, viscosity management, in-line viscometers, ViscoPro 2100

Spring and wire products are a substantial market – estimated to reach $468B by the end of 2020. Wire is widely used in manufactured goods, including electronics, automobiles, motors, transformers, and a wide array of other products. The coating on the wire is possibly the single most important variable in wire quality, and viscosity plays an important role in ensuring quality.

Ensuring Quality of Wire Coatings with Viscometry

Dec 16, 2020 9:28:49 AM / by Patrick Riley posted in viscosity control, viscosity management, Coating, in-line viscometers, ViscoPro 2100, process viscometer

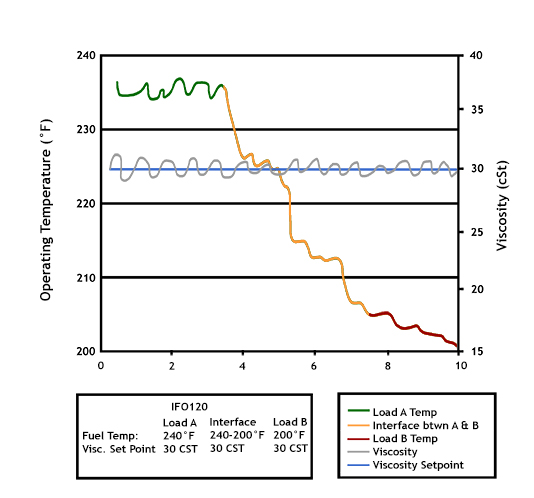

Determining the Viscosity of Heavy Fuel Oils

Dec 8, 2020 3:44:17 PM / by Patrick Riley posted in viscosity measuring solution, viscosity control, heavy fuel oil viscosity, viscosity management, in-line viscometers

In shipping vessels, “bunker” refers to the fuel and lube oils that are stored on the ship and used for machinery operation. When the fuel or oil is intended for transfer to another ship for use in its machinery, the operation to transport the oil is called “bunkering.”

Optimize coating applications through tighter viscosity control

Dec 2, 2020 9:07:18 AM / by Patrick Riley posted in viscosity measuring solution, viscosity control, coating viscosity, viscosity management, Coating, ViscoPro 2100

When it comes to coatings, product quality can live or die by viscosity. A too-viscous mixture can result in bubbling and an inconsistent, bumpy, “orange-peel” texture. A solution that is not viscous enough can result in a coating that is too thin, drippy, or saggy. Plus, depending on the application, a coating that is too thin may not provide the necessary top-coat protection. In either case, a coating that has an off-spec viscosity in either direction can result in product rejection or product failure.

Measuring viscosity in asphalt leads to a reduction in energy usage

Nov 17, 2020 2:59:47 PM / by Patrick Riley posted in viscosity control, asphalt viscosity, ViscoPro 2100, process viscometer

November in New England, where Cambridge Viscosity is headquartered, is the time of year when our leaves finish falling and the weather turns cold. Soon, it will be snowy and frigid in Massachusetts. (Who are we kidding – we had our first snowfall in October this year!) Inspired by the chill in the air, we thought we’d talk about some of the challenges of measuring viscosity in colder atmospheric conditions, where ambient temperatures fall below 50 °F for part of the year

CVI Supports R&D for the Use of Nanoparticles in Heat Transfer Fluids

Nov 11, 2020 4:08:10 PM / by Patrick Riley posted in viscosity measuring solution, viscosity control, viscosity management, viscometer support

It’s always interesting to see how our customers use the Cambridge Viscosity viscometers to support product development and continuous improvement. Our customers monitor viscosity in thousands of unique applications – they develop pharmaceuticals that improve quality of life, they test engine oils to make sure cars and airplanes operate more efficiently and heavy marine fuel so shipping companies to achieve proper fuel efficiency. They monitor the viscosity of coatings, to create high-quality lenses of all types. And, in the oil and gas industries, our viscometers provide the data necessary to understand the makeup of the raw material, so it can be handled and processed appropriately.

The Connection Between Laboratory Viscosity Measurement and Quality

Nov 4, 2020 4:08:49 PM / by Patrick Riley posted in coating viscosity, thin film coating, medical devices, temperature compensated viscosity

The past eight months have presented us with interesting challenges – and those challenges have definitely hit the medical device industry hard. The manufacturing supply chain has experienced shortages, which means medical device manufacturers are being asked to bring their technologies to market faster. Emergency authorizations mean pre-market review is putting pressure on the R&D process. Viscosity measurement is a critical component in helping medical device manufacturers meet these challenges and get their products out the door faster and at the highest levels of quality.