When compressor manufacturers design a new compressor model, part of the process includes determining the type of refrigerant and the accompanying lubricating oil, which is necessary to reduce friction on metal parts, reduce wear on the compressor, and extend the life of the system. The company must conduct extensive testing to ensure proper energy efficiency and functionality. The lubricant has a significant impact on the performance of the compressor. Over-lubrication can impact the compressor’s ability to cool properly, but too much refrigerant will lead to more wear and a shorter compressor lifecycle.

Recently, a group of researchers, Jianhua Wu, Zhenhua Chen, Jie Lin, and Jinbo Li, from Xi’an Jiaoton University published a paper titled “Experimental analysis on R290 solubility and R290/oil mixture viscosity in oil sump of the rotary compressor”. They conducted a set of experiments on both the compressor performance and system psychometric chambers for an R290 rotary compressor with mineral oil having high viscosity.

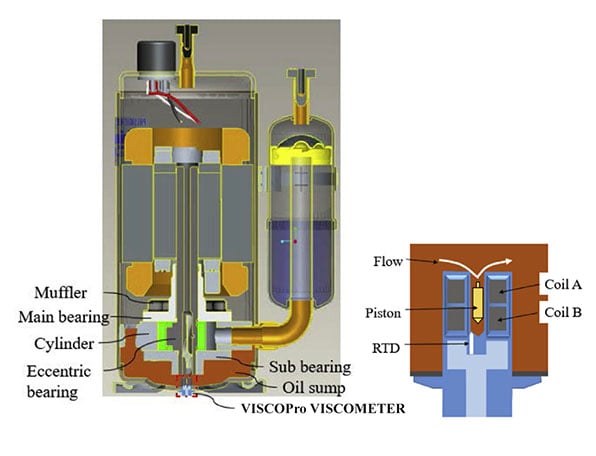

Window-unit air conditioners that are often used in homes usually apply rotary-type compressors with a high-pressure shell containing various types of bearings, pistons, and friction shells. The functionality of these bearings and friction pairs is an important factor for the performance and reliability of the compressor. The viscosity of the lubricating oil and refrigerant mixture depends on the solubility of the refrigerant in the oil at a given temperature. When the refrigerant is more soluble, the viscosity in the oil sump will decrease. If the lube oil/refrigerant mixture stays at a low viscosity for an extended period of time, bearing wear will increase, leading to problems.

The researchers wanted to better understand the variables affecting operating viscosity of oil with dissolved refrigerant – specifically for R290 which is a feasible alternative to the more common R22 or R410A in residential air conditioners. One of the challenges they faced was obtaining accurate, real-time refrigerant solubility and mixture viscosity in oil sump using only the saturated mixture properties. In the research, they took a look at the practical solubility and viscosity of R290 refrigerant in mineral oil with a high viscosity grade.

For one of their experiments, they installed a VISCOpro with a SPC501 sensor at the bottom of the compressor to measure the viscosity of oil before it entered the crankshaft hole. The accuracy and reading error of the viscometer were +/- 0.1% and +/-0.8% respectively.

The 290 refrigerant is flammable, and they wanted to know if it could be safety used in compressors, and if it would perform correctly, making it a viable alternative for traditional refrigerants. Without the VISCOpro, the researchers were able to make theoretical calculations that allowed them to make predictions offline. With the VISCOpro and SPC501 sensor, they were able to make empirical measurements in real time.

In order to capture in-line measurements, they required a small, rugged, robust instrument that would handle the temperatures of the sump and the actual operating conditions. The VISCOpro, with a viscosity range of 0.2-20,000 cP and an accuracy of greater than 1%, helped the research team successfully complete their research project.

The entire paper was published in the International Journal of Refrigeration is available for purchase online through Science Direct at https://www.sciencedirect.com/science/article/abs/pii/S0140700718302718.