When it comes to air conditioning and compressor systems, achieving ideal operating efficiency is about balance. Too much lubricant means the compressor or cooling system won’t cool properly, and too much refrigerant increases bearing wear and reduces the system life. Thicker oil lubricates better, but it also means there is an increase in drag, and more power is needed to rotate the compressor. Manufacturers must consider all these variables when manufacturers designing their equipment. Each new design requires significant testing to ensure performance and energy efficiency.

When it comes to air conditioning and compressor systems, achieving ideal operating efficiency is about balance. Too much lubricant means the compressor or cooling system won’t cool properly, and too much refrigerant increases bearing wear and reduces the system life. Thicker oil lubricates better, but it also means there is an increase in drag, and more power is needed to rotate the compressor. Manufacturers must consider all these variables when manufacturers designing their equipment. Each new design requires significant testing to ensure performance and energy efficiency.

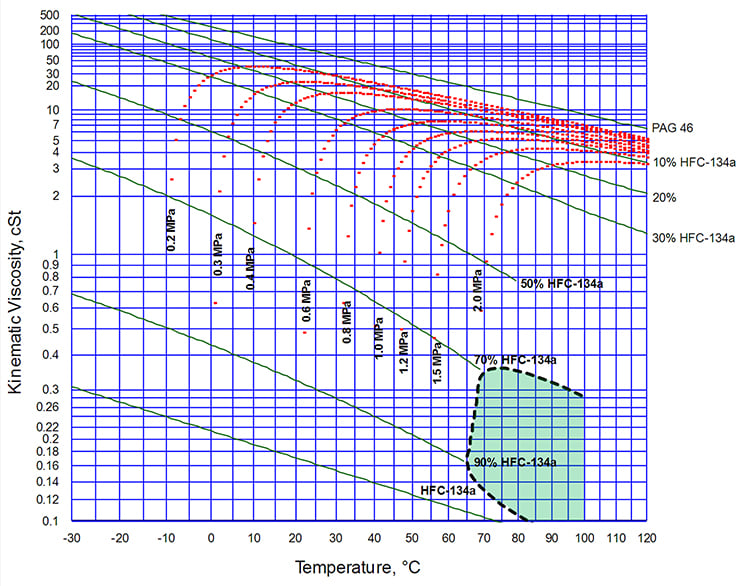

The right refrigerant/lubricant mixture means optimal performance of the compressor, so knowing the viscosity of the blend is extremely important. Viscosity is a function of pressure, temperature, and solubility. All three are needed for compressor design.

Daniel charts use equations of state to determine the relationship between viscosity, temperature, pressure, and solubility and are used to profile lubrication/refrigerant pairings to ensure optimum performance and efficiency. Cambridge Viscosity’s viscometers are the industry standard for Daniel chart development.

A Daniel chart profiles the relationship between pressure, temperature, and solubility

Cambridge Viscosity's VISCOpro line of micro process viscometer’s includes the only sensors that are small enough to be installed directly in the compressor pump. In addition to being extremely small, the viscometer is flexible enough to work with proven accuracy and reliability under a wide range of pressures and temperatures. In a typical installation, the 571 sensor or 501 sensor is mounted directly in the compressor pump or pressurized line, where it captures continuous viscosity and temperature measurements through the test cycle.

The CVI viscometer is unique in its ability to measure low volumes at high temperatures (190 °C) and high pressures (2000 psi+).

Results

- Robust measurements under pressures exceeding 1000 psi and temperatures up to 190 °C

- Highly repeatable measurement — better than 0.8% of reading

- Low sample volume requirement

- Smallest sensor in the industry

- All 316L stainless-steel, wetted parts

- Accuracy (1%)