Each new Cambridge Viscosity viscometer ships with a certified hydrocarbon-based viscosity reference standard which is used to confirm proper system operation and accuracy. A data sheet with viscosity versus temperature is included to provide precise viscosity values in increments of 0.1C.

How do I know my new viscometer is working properly?

Jul 23, 2020 8:00:00 AM / by Patrick Riley posted in monitor viscosity, in-line viscometers, viscometer

How to Use Temperature Compensated Viscosity on my Viscometer

Jul 15, 2020 4:06:14 PM / by Patrick Riley posted in viscosity measuring solution, viscosity control, How to measure viscosity

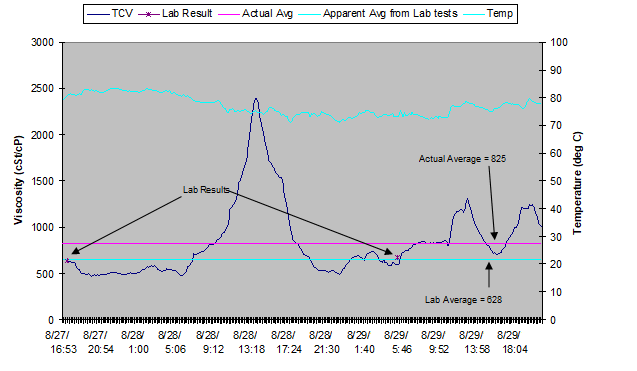

Viscosity and temperature are interdependent. Correlating viscosity data between the process and the laboratory can be difficult, especially when the process temperature fluctuates and the lab viscosity measurements are taken at a fixed temperature. More often than not, periodic lab viscosity measurements are not adequate for process control as process changes can result in drift and the result is that the actual viscosity od the end-product and end up significantly different from the lab projection.

The answer to this problem is TCV or Temperature Compensated Viscosity.

TCV provides an accurate calculation of viscosity at a specific reference temperature which differs from actual process conditions. This function assumes a linear relationship between temperature and the double logarithm of viscosity and is based on ASTM Method D341. Once enabled, TCV is highly accurate for Newtonian hydrocarbons and yields a reliable approximation for most other Newtonian and non-Newtonian fluids.

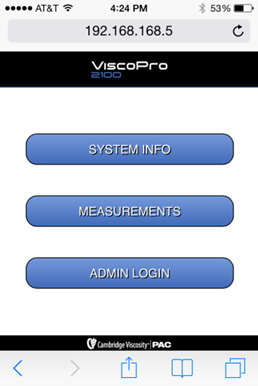

The ViscoPro2100 viscometer incorporates a TCV feature and it can be enabled through the Web User Interface (UI). The following article provides you with the necessary information to enable and set-up the Temperature Compensated Viscosity feature on your viscometer so that you can adequately correlate the process viscosity and laboratory viscosity and provide uniform product to your customers.

How to Log Into a Viscometer with a Smart Phone

Jun 22, 2020 1:36:00 PM / by Patrick Riley

Smart phones are everywhere and bring us a level of convenience and connectedness that was unimaginable even a decade ago. You can use your phone to order food, fill out the census, trade stocks, make complex calculations and a million other things. Now you can also talk to your viscometer without the need for a display interface or networking the device. Using a wireless fob connected to the Ethernet port on the viscometer, you can download logs, change units and settings or even calibrate the device. We've developed safe, secure and reliable convenience for viscometer users.

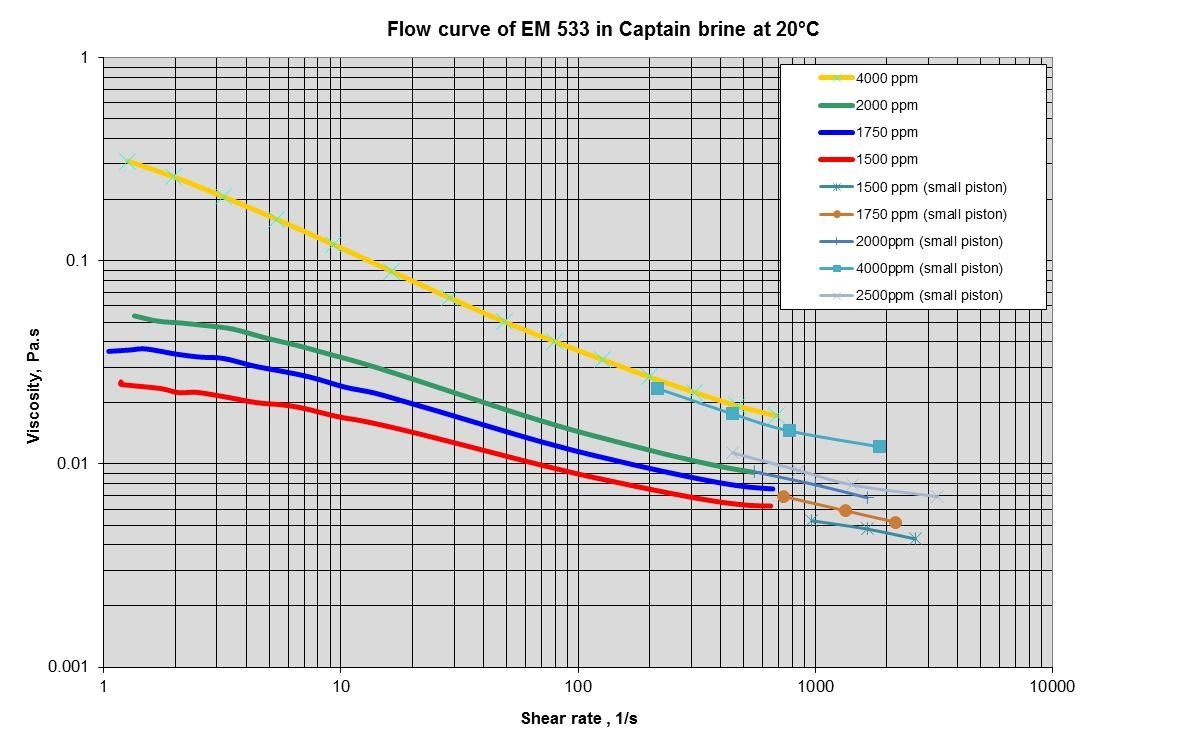

Creating Shear Sweeps with an Oscillating Piston Viscometer

Mar 30, 2020 12:00:00 AM / by Patrick Riley posted in in-line viscometers

Using the oscillating piston method to produce rheometric data by providing viscosity values at known shear rates with non-Newtonian fluids.

Looking at the Future of Viscosity Management

Feb 28, 2020 12:00:00 AM / by Patrick Riley posted in in-line viscometers

Metong Machinery Company uses In-Line Viscometers for Asphalt Coating

Jan 21, 2020 8:00:00 AM / by Admin posted in VISCOpro2000, process viscometers, monitor viscosity, viscosity control, fuel combustion, asphalt viscosity

Boston—Cambridge Viscosity’s in-line viscometer, VISCOpro 2000, is being used by Zhejiang Metong Machinery Company, a leading producer of road construction and maintenance equipment.

The company’s primary products include truck-mounted asphalt systems sold worldwide, asphalt melting equipment and the largest emulsified asphalt plant in China.

Metong’s MT-AR50 Portable Reaction Tank is specially designed for reaction, storage and transportation of rubberized asphalt. Used to pave asphalt roads, the waste tire rubber powder and rubberized asphalt mixture improves pavement function, extends service life and reduces the environmental pressure caused by waste tires. Rubberized asphalt meets the national policy of building a conservation-minded society and developing a cyclic economy.

Metong uses Cambridge’s in-line viscometers to monitor and control asphalt viscosity for their truck-mounted systems. Viscosity is key in monitoring the quality of the rubberized asphalt. In the tank, the asphalt’s viscosity changes according to temperature and the length of time it is contained. The sensors help to maintain constant viscosity by adapting the temperature as needed to obtain a more consistent spray pattern, allowing an even coating to be sprayed onto the road for a higher quality result.

“Viscosity is one of the most important parameters for providing consistent spray patterns for our asphalt application,” explains Technical Engineer Mr. Yang. “We considered several other technologies such as rotational and vibrational viscometers but found the Cambridge viscometer to be the best choice for us due to its compact size, simple design and rugged construction,” says Technical Director Mr. Feng.

About Cambridge Viscosity

Cambridge Viscosity is the leading supplier of automated viscometers used by oil exploration and refining, coating, chemical and life science companies to optimize product and process performance. Cambridge Viscosity's sensors and viscometer systems conform to ASTM, DIN, JIS and ISO standards, with a range of models designed to meet specific industry and application needs.

Type certifications include ATEX, CE and FM. CSA certification is available upon request. Cambridge's global reach provides application engineering support and service wherever and whenever needed.

New Rugged Viscometer Withstands Harsh EOR Conditions

Nov 20, 2019 8:00:00 AM / by Admin posted in VISCOpro2000, process viscometers, 393 sensor, Exploration, EOR, ViscoPro 2100

Boston—Cambridge Viscosity has developed a rugged, RTJ-flanged in-line process viscometer for a leading global oil company’s Enhanced Oil Recovery (EOR) application in the North Sea. Cambridge designed the SPL-393 viscometer for use offshore, where safety and reliability are not just a priority but also a necessity. The new viscometer meets all electrical, plumbing material, pressure and temperature requirements for use on a platform where environmental conditions can reach extremes.

The sensor connects into a pipeline using a standard ANSI class 900/1500 2" RTJ round flange. The rugged 316SS construction can withstand up to 2200 PSI and 190 degrees C, and has long penetration for large diameter pipes. The SPL 393 satisfies ASME PTC 19.3 Thermowells requirements. The new sensor is designed for highly accurate, repeatable viscosity readings and clean-in-place simplicity. Coupled with Cambridge's standard VISCOPro 2000 or ViscoPro 2100 electronics, the sensor has sophisticated multi-shear compatibilities.

Cambridge Director of Engineering Dan Airey says, "We are very excited to introduce this product designed to meet the specific needs of the petroleum industry. The initial application of the SPL-393 sensor in EOR oil production improves production efficiency while withstanding harsh offshore drilling conditions. Our customer is achieving repeatable, reliable viscosity measurements that contribute to better control of EOR operations.”

About Cambridge Viscosity

Cambridge Viscosity, a leader in small sample viscometer systems for laboratory and process environments, designs automated viscometers used worldwide in petroleum, exploration and refining applications to ensure accurate viscosity in both lab and operations. Cambridge’s worldwide reach is important for providing application engineering support and service wherever and whenever needed.

Cambridge Viscosity’s sensors and viscometer systems conform to ASTM, DIN, JIS and ISO standards, with a range of models designed to meet specific industry and application needs.

To learn more visit www.cambridgeviscosity.com.

Medical and Optical Coating Viscosity Control: Lessons Learned

Oct 17, 2019 8:05:00 AM / by Admin posted in process viscometers, viscosity control, coating viscosity, biotech, Coating

Uniform film thickness is essential for effective optical and medical coatings. If the film thickness on a medical device is not correct, the product will not interact properly with the body. If an optical film is too thin, its product efficacy is impaired; if too heavy, visual performance is frequently compromised. Viscosity is critical for maintaining desired film thickness. As the preferred viscometer supplier for many medical and optical coatings worldwide, Cambridge Viscosity has identified seven critical factors for optimal performance.

Refinery Viscosity Management: Lessons Learned

Sep 19, 2019 8:00:00 AM / by Admin posted in oil viscosity, refining, asphalt viscosity

Viscosity is one of the most important measures of refinery product quality. All refinery products are graded by viscosity.

Significant efforts are spent throughout refinery operations in achieving viscosity targets. Working with customers worldwide, Cambridge Viscosity has identified five factors most important for efficient and effective refinery viscosity management.

Leading Refiner Uses Explosion-proof Enclosures for Asphalt Viscosity

Jul 31, 2019 1:12:00 PM / by Admin posted in chemical processing, enclosure, explosion-proof, refining

Faced with improving viscosity control in a challenging processing environment, a leading South American oil refiner turned to Cambridge Viscosity. Cambridge responded by developing explosion-proof mounting enclosures to augment the viscosity control system the company relies upon for highly accurate viscosity measurement.

Perfecting Compressor Refrigerant-Oil Balance

Jun 18, 2019 8:00:00 AM / by Admin posted in PVT, oil analysis, compressor viscosity, refrigerant viscosity

For Immediate Release

Major Refinery Improves Profitability with Viscosity Monitoring

Apr 1, 2019 10:00:00 AM / by Admin posted in process viscometers, 392 sensor, oil viscosity, monitor viscosity, refining, VISCOpro1600, compressor viscosity

Boston—Machinery failures, downtime and maintenance labor costs can kill a refiner’s bottom line profits. A major US oil company with refinery installations in North and South America has installed several Cambridge Viscosity VISCOpro viscometers to monitor oil viscosity, providing engineers with real-time information on oil quality. The viscometers utilize Cambridge’s 392 process sensors and are Class 1 Div 1 Group B, C, and D certified.

Expanded Lubrication Oil for Gas Compressors

Mar 12, 2019 7:59:00 AM / by Admin posted in process viscometers, lube oil, refining, gas compressor, oil monitoring, compressor viscosity

FOR IMMEDIATE RELEASE

Controlling Viscosity for Uniform Fine Wire Coating

Jan 24, 2019 10:00:00 AM / by Admin posted in wire coating, coating viscosity, Coating

Boston—How do you control coating on wire that is finer than a human hair? This is the challenge faced by manufacturers of 30 – 300 micron diameter wire known as winding wire, magnet wire or fine wire. These wires are key components in electric motors, transformers and electric coils required in appliances, cars and other powered devices.

H2S-Friendly High Pressure High Temperature Viscometers

Dec 11, 2018 12:00:00 AM / by Admin posted in PVT, reservoir fluid, high temperature viscometer, Exploration, high pressure viscometer, H2S

FOR IMMEDIATE RELEASE