Using the oscillating piston method to produce rheometric data by providing viscosity values at known shear rates with non-Newtonian fluids.

*The calculations for determining shear rate based on CVI viscosity data can be found in technote TN-03-0026. Contact sales@cambridgeviscosity.com for a copy of this paper.

Overview:

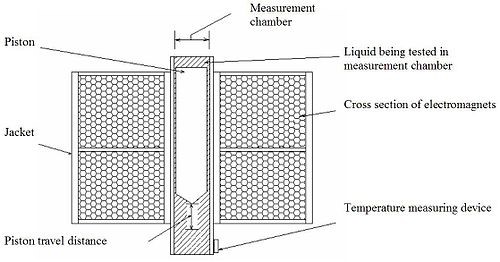

With the oscillating piston viscometer, measurements are taken whereby a sample is first introduced into the thermally controlled measurement chamber where the piston resides. Electronics drive the piston into oscillatory motion within the measurement chamber with a controlled magnetic field. A shear stress is imposed on the liquid (or gas) due to the piston travel and the viscosity is determined by measuring the travel time of the piston. The construction parameters for the annular spacing between the piston and measurement chamber, the strength of the electromagnetic field, and the travel distance of the piston are used to calculate the viscosity according to Newton’s Law of Viscosity. They also allow for the calculation of the shear rate imparted by the measurement at any given viscosity value.

Cross-section of Oscillating Piston Viscometer

The viscometer is calibrated to a specific viscosity range using two NIST traceable standards, one for the higher end of the viscosity range (50%-125% full-scale) and the other for the lower end (0-15% full-scale). The piston size is equated to one of thirteen calibrated ranges (between 0.02 & 10,000cP), with the largest diameter piston used for the lowest viscosity range and the smallest diameter piston used for the highest viscosity range. In any of the thirteen viscosity ranges, the viscometer is calibrated at a fixed force to a “time vs. viscosity” curve for Newtonian fluids where the high-end travel time is 26 seconds at the full-scale viscosity.

The force applied to drive the piston to achieve the 26 second cycle time (setting the high-end of the calibration curve) is automatically calculated by the viscometer processor’s auto-calibrate routine. The force applied to the piston is approximately 450mA, but will be higher or lower depending on variations in the dimensions of the measurement chamber or the piston. The auto-calibrate routine selects the closest mA force necessary to achieve the appropriate cycle time and then a correction factor is applied to eliminate any offset.

Measuring Non-Newtonian Fluids:

It is possible to manually calibrate a viscosity range at a force (mA level) other than that calculated by the auto-calibrate routine to meet the 26 second cycle time criteria and then use the correction factor to adjust the “time vs. viscosity” curve so that the system will correctly measure the viscosity of a Newtonian fluid. This will produce a viscosity reading at a shear rate different from that of the same viscosity value generated under a calibration done by the system’s automatic routine.

The VISCOpro/VISCOlab 2000 electronics will accept up to 40 calibration indexes. A series of these alternate calibrations can be entered into the viscometer via the serial port and used to produce a shear sweep for a non-Newtonian fluid.

Application Overview:

Using a Cambridge Viscosity viscometer for measuring various concentrations of polymer in brine solutions at different shear-rates for correlation to data obtained on a Bohlin Rheometer. The testing is to determine the feasibility of using oscillating piston viscometers to control the mixing of various concentrations of polymer solutions for use in Enhanced Oil Recovery (EOR) applications an active field.

Summary:

The viscometer’s accuracy and repeatability were within specification. It was successful in differentiating a series of non-Newtonian polymer concentrations at various shear rates to complete shear curve profiles for the fluids. Review of the data showed strong correlation to data obtained by a Bohlin rheometer in the range of 127-1000 sec-1.

Testing:

The testing was performed at an R&D laboratory at a major polymer maufacturer using a VISCOpro 2000 electronics with SPC-311 sensor. The VISCOpro 2000 electronics are the same platform as the ViscoLab series and the SPC/L-311 differs from the 400 series (i.e. SPL-440) and 500 series (i.e. SPC/L-501 and SPC/L-571) only on scale and pressure rating.

The unit was calibrated with 3 ranges (2.5-50, 5-100, 25-500) each having 3 to 4 shear points or calibrated drive forces. Having these different drive forces allowed for measurement a given polymer at multiple shear-rates and then compare it with the Bohlin rheometer results.

The customer was interested in measuring 6 concentrations:

- 1500ppm

- 1750ppm

- 2000ppm

- 2500ppm

- 4000ppm

- 10,000ppm

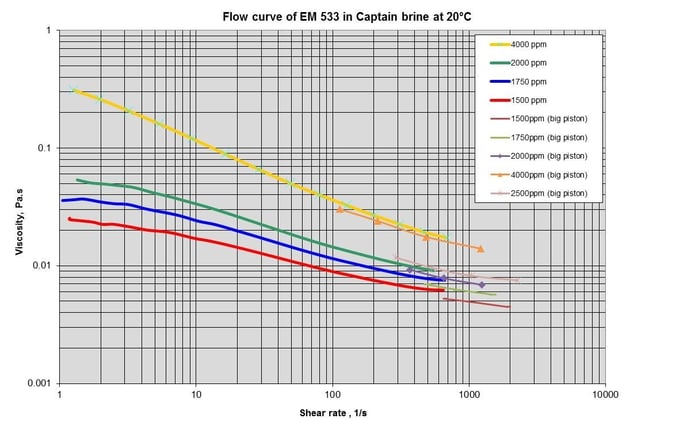

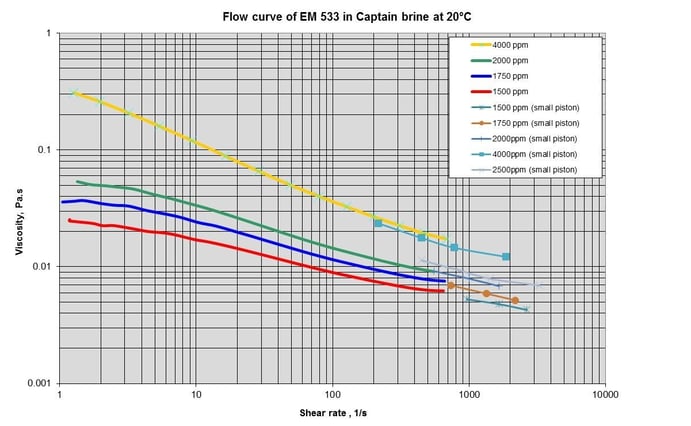

Concentrations 1500 to 4000ppm were measured with both the 2.5-50cP and 5-100cP ranges. The extended procedure was performed in order to determine the lowest achievable shear rate for these specific materials. Based on the testing the shear rate varied from 100 to 4000 sec-1 with the 2.5-50cP range and 200 to 6000 sec-1 with the 5-100cP piston. Graphed data can be found in figures 1 and 2 below. The customer was particularly interested in the concentration range of 1750 to 2500 because they want 2000ppm concentration injected down-hole during operation. The 10,000ppm concentration was measured using the 25-500cP range and shear rate varied from 29 to 450 sec-1. This concentration was of interest because this is the delivered concentration to the oil rig before any water is mixed in.

Fig 1: 2.5-50cP data

Fig 2: 5-100cP data

Conclusion:

The oscillating piston method, while not a rheometer, can produce rheometric data by providing viscosity values at known shear rates with non-Newtonian fluids. The unique technology allows for the manipulation of the shear rate either through changing of the piston diameter or through the force applied to drive the piston through the fluid. The calculations have been defined in the Shear Rate Technote (TN03-0026).