Ensuring Quality of Wire Coatings with Viscometry

Dec 16, 2020 9:28:49 AM / by Patrick Riley posted in viscosity control, viscosity management, Coating, in-line viscometers, ViscoPro 2100, process viscometer

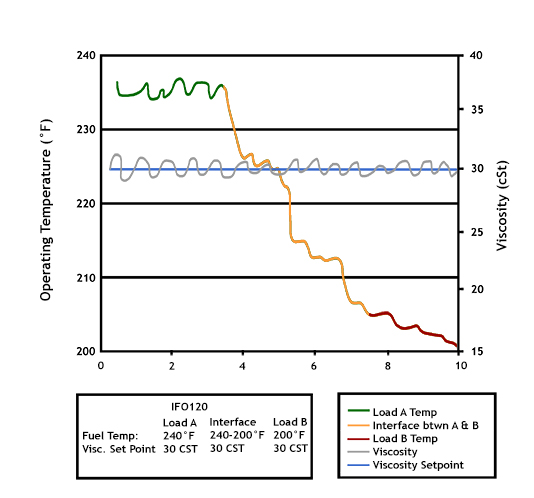

Determining the Viscosity of Heavy Fuel Oils

Dec 8, 2020 3:44:17 PM / by Patrick Riley posted in viscosity measuring solution, viscosity control, heavy fuel oil viscosity, viscosity management, in-line viscometers

In shipping vessels, “bunker” refers to the fuel and lube oils that are stored on the ship and used for machinery operation. When the fuel or oil is intended for transfer to another ship for use in its machinery, the operation to transport the oil is called “bunkering.”

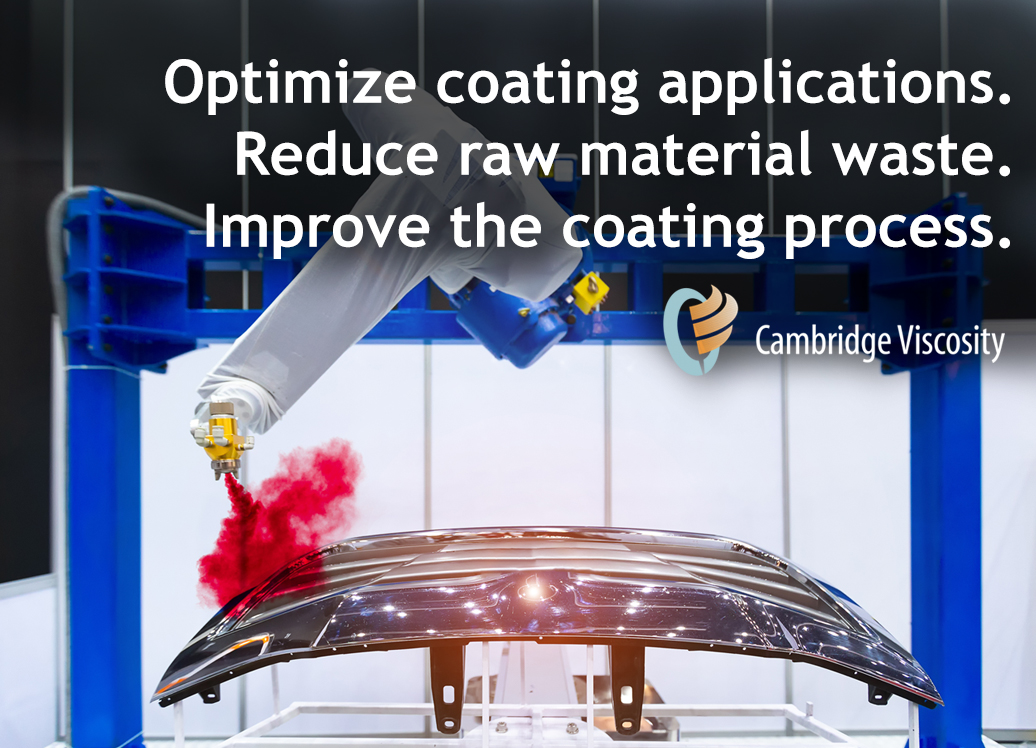

Optimize coating applications through tighter viscosity control

Dec 2, 2020 9:07:18 AM / by Patrick Riley posted in viscosity measuring solution, viscosity control, coating viscosity, viscosity management, Coating, ViscoPro 2100

When it comes to coatings, product quality can live or die by viscosity. A too-viscous mixture can result in bubbling and an inconsistent, bumpy, “orange-peel” texture. A solution that is not viscous enough can result in a coating that is too thin, drippy, or saggy. Plus, depending on the application, a coating that is too thin may not provide the necessary top-coat protection. In either case, a coating that has an off-spec viscosity in either direction can result in product rejection or product failure.

Measuring viscosity in asphalt leads to a reduction in energy usage

Nov 17, 2020 2:59:47 PM / by Patrick Riley posted in viscosity control, asphalt viscosity, ViscoPro 2100, process viscometer

November in New England, where Cambridge Viscosity is headquartered, is the time of year when our leaves finish falling and the weather turns cold. Soon, it will be snowy and frigid in Massachusetts. (Who are we kidding – we had our first snowfall in October this year!) Inspired by the chill in the air, we thought we’d talk about some of the challenges of measuring viscosity in colder atmospheric conditions, where ambient temperatures fall below 50 °F for part of the year

CVI Supports R&D for the Use of Nanoparticles in Heat Transfer Fluids

Nov 11, 2020 4:08:10 PM / by Patrick Riley posted in viscosity measuring solution, viscosity control, viscosity management, viscometer support

It’s always interesting to see how our customers use the Cambridge Viscosity viscometers to support product development and continuous improvement. Our customers monitor viscosity in thousands of unique applications – they develop pharmaceuticals that improve quality of life, they test engine oils to make sure cars and airplanes operate more efficiently and heavy marine fuel so shipping companies to achieve proper fuel efficiency. They monitor the viscosity of coatings, to create high-quality lenses of all types. And, in the oil and gas industries, our viscometers provide the data necessary to understand the makeup of the raw material, so it can be handled and processed appropriately.

The Connection Between Laboratory Viscosity Measurement and Quality

Nov 4, 2020 4:08:49 PM / by Patrick Riley posted in coating viscosity, thin film coating, medical devices, temperature compensated viscosity

The past eight months have presented us with interesting challenges – and those challenges have definitely hit the medical device industry hard. The manufacturing supply chain has experienced shortages, which means medical device manufacturers are being asked to bring their technologies to market faster. Emergency authorizations mean pre-market review is putting pressure on the R&D process. Viscosity measurement is a critical component in helping medical device manufacturers meet these challenges and get their products out the door faster and at the highest levels of quality.

Viscosity Measurement Helps to Overcome Manufacturing Challenges

Oct 21, 2020 6:00:00 AM / by Patrick Riley posted in viscosity measuring solution, viscosity control

Quality control and the ability to meet the demand for rapidly changing technologies are big challenges for electronic components manufacturers. Parts like capacitors – which can be as small as the head of a pin in certain applications – must meet critical performance targets. Cambridge Viscosity helped a U.S.-based manufacturer overcome one of its manufacturing challenges. The company wanted to use a paste to apply dielectric material with highly precise characteristics in a paste form onto a capacitor substrate, which had a significant impact on the final product characteristics.

Eliminate Paint Problems Before They Happen

Oct 7, 2020 9:46:49 AM / by Patrick Riley posted in coating viscosity, viscometer, process viscometer, paint viscosity

In an auto industry that is more competitive than ever, any technology that enhances quality is well worth considering – especially when the benefits far outweigh any costs.

How often should I calibrate my viscometer?

Sep 30, 2020 11:16:05 AM / by Patrick Riley posted in process viscometers, viscosity, viscometer calibration

This question gets asked frequently due to concerns about validating data and measurement using inline or laboratory viscometers. The answer ultimately depends on how critical the measurement is and the type of viscometer used in your application.

Oil Viscosity Index Standardized Using In-line Viscometer

Sep 10, 2020 8:26:16 AM / by Admin posted in process viscometers, oil viscosity, refining

A leading worldwide maker of premium base oil for lubricants, based in the western United States, has standardized on Cambridge Viscosity

CASE STUDY: Using Viscosity Measurement to Achieve Consistent Coatings

Sep 2, 2020 1:29:00 PM / by Patrick Riley posted in coating viscosity, ViscoPro 2100, Glass coating viscosity, thin film coating, madico

Monitoring the viscosity of coating products to achieve higher product quality and reduce maintenance downtime

CHALLENGE

Controlling the viscosity of coating products is a significant challenge for manufacturers across a wide range of applications, from optical and medical to drum coating. The fluids are often difficult to work with and must be formulated and used within strict parameters to achieve the desired film weight, thickness, and image characteristics.

Preventative maintenance of my process viscometer

Aug 26, 2020 11:19:26 AM / by Patrick Riley posted in monitor viscosity, in-line viscometers, viscometer, process viscometer

Cambridge Viscosity process viscometers are known for robust operation and reliability in viscosity measurements. Performing scheduled Preventative Maintenance (PM) on your Cambridge Viscosity viscometer is vital to system operation, longevity, and verification. Cambridge Viscosity recommends performing PM on your viscometer on an annual basis as defined in our Operational Manual. PM can be performed at more frequent intervals if deemed necessary due to internal QA or other departmental policies.

Minimizing Piping and Volume Requirements for Viscosity Measurements

Aug 19, 2020 8:50:38 AM / by Patrick Riley posted in coating viscosity, eyewear viscosity

Most viscometer sensors require a large tee or housing to accept their sample volume requirements. This is fine in larger diameter process lines, say 2” and above, but it becomes an engineering hurdle when space is a premium and overall system volumes are limited, such as in dip coating applications for medical devices or optical lenses. There are in-line viscosity solutions available for small diameter process lines and low volume systems.

How to Field Calibrate Your Viscometer

Aug 12, 2020 8:00:00 AM / by Patrick Riley posted in process viscometers, viscosity measuring solution, viscosity management, in-line viscometers, viscosity

Comparing on-line viscosity measurements to the lab is challenging. Process conditions can change, laboratory samples can off-gas, fluids may be non-Newtonian and measure

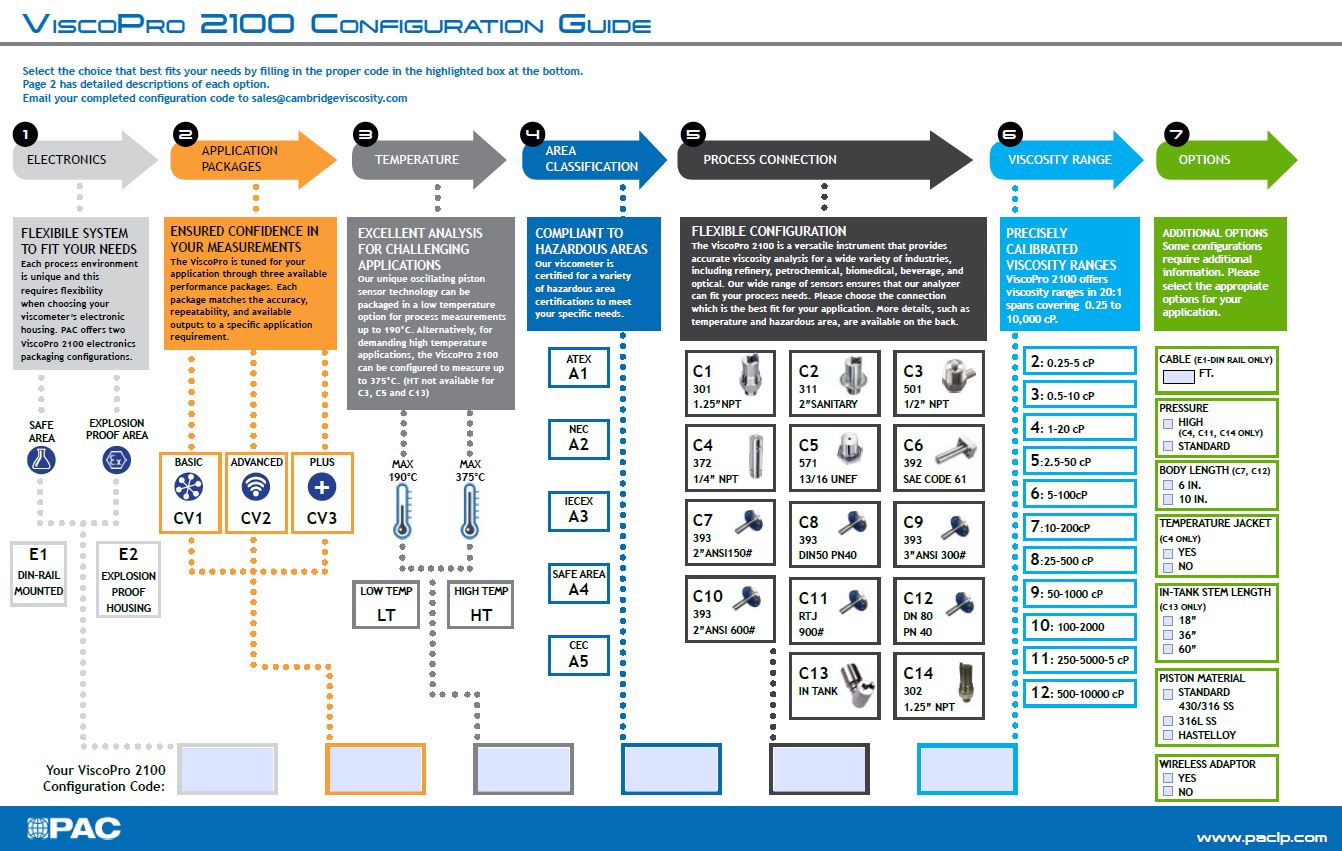

How to Configure my Viscometer

Aug 5, 2020 8:08:45 AM / by Patrick Riley posted in ViscoPro 2100, viscometer

The Viscometer Configuration Guide is used to build our viscometer to meet your unique process needs. Our VISCOpro 2100 platform offers a range of options for different mounting, outputs, and sensors choices. The guide steps you through choosing these options and builds a specific product code which can be used for specifications, pricing, drawings, and literature.