The past eight months have presented us with interesting challenges – and those challenges have definitely hit the medical device industry hard. The manufacturing supply chain has experienced shortages, which means medical device manufacturers are being asked to bring their technologies to market faster. Emergency authorizations mean pre-market review is putting pressure on the R&D process. Viscosity measurement is a critical component in helping medical device manufacturers meet these challenges and get their products out the door faster and at the highest levels of quality.

The past eight months have presented us with interesting challenges – and those challenges have definitely hit the medical device industry hard. The manufacturing supply chain has experienced shortages, which means medical device manufacturers are being asked to bring their technologies to market faster. Emergency authorizations mean pre-market review is putting pressure on the R&D process. Viscosity measurement is a critical component in helping medical device manufacturers meet these challenges and get their products out the door faster and at the highest levels of quality.

Viscosity & Biomedical Products

Biomedical products like catheters, hypodermic needles, and replacement artificial heart valves require a precisely uniform coating, which must be maintained throughout the manufacturing process. If the thickness isn’t correct, the products may not interact correctly with the human body and could fail. Thickness is a measure of solids in the coating fluid, and is impacted by temperature, which can vary significantly throughout a typical manufacturing process. This makes applying the proper film thickness the most difficult part of most coating applications, and an uneven coating can make the end-product unusable. With coating materials being expensive, and VOC-based solvents being tightly controlled, errors in film thickness can be costly. In addition to the loss of costly coating materials and environmental costs associated with manufacturing, scrap reduces yield.

A Viscometer That Compensates for Temperature

At this point, you have a few options. One option is to perform periodic manual viscosity checks of the coated product. This method is known as destructive testing, where products are incrementally taken off the assembly line and cut in half to determine coating thickness. Not only is this expensive, labor-intensive, and time consuming, it can also be negatively impacted by human error.

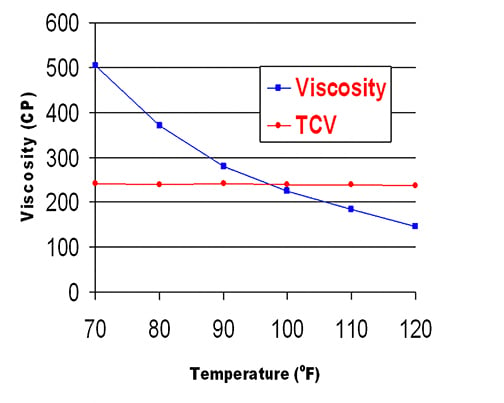

Cambridge Viscosity offers an alternative solution. Because varying temperature throughout the process impacts viscosity, it is necessary to negate the effects of temperature during the measurement process. The ViscoPro 2100 viscometer does this through temperature-compensated viscosity (TCV), which shows what the viscosity would be at a fixed reference temperature, regardless of fluctuations in atmosphere. With this process, the effects of temperature on viscosity measurement are negated, resulting in an accurate reflection of the percent of solids in the fluid to ensure that a proper and uniform film thickness is applied.

With in-line viscosity measurement that incorporates TCV, it’s possible to achieve significant cost savings by keeping the coating machines running at the most efficient levels, without interrupting the process to determine changes in viscosity due to temperature. The real-time, automatic measurement and control reduces labor requirements and laboratory time and reduces the amount of scrap waste. Plus, it helps to improve the overall uniformity and quality of the end product.

Additionally, ViscoPro 2100 is ideal for small areas. It uses the 372 sensor with ¼” inlet and outlet ports, which was developed for small system volumes, which are characteristic of coating applications. The small sensor is suitable for hazardous areas and makes installation and maintenance easier. Plus, where sample conditioning is required, small sensors like the 372 require smaller amounts of fluid treatment.

Additionally, ViscoPro 2100 is ideal for small areas. It uses the 372 sensor with ¼” inlet and outlet ports, which was developed for small system volumes, which are characteristic of coating applications. The small sensor is suitable for hazardous areas and makes installation and maintenance easier. Plus, where sample conditioning is required, small sensors like the 372 require smaller amounts of fluid treatment.

This method yields significant benefits for medical device manufacturers.

- Improves yield by reducing scrap

- Minimizes amount of solvents necessary in the process

- Allows operators to maintain control over the coating solids, regardless of temperature

- Eliminates the need for costly destructive testing procedures

- Offers traceability of the product throughout the process

For more information on temperature compensated viscosity measurement, visit this blog post:

Have questions? Send us a message, and one of our application experts will get back to you.