When it comes to air conditioning and compressor systems, achieving ideal operating efficiency is about balance. Too much lubricant means the compressor or cooling system won’t cool properly, and too much refrigerant increases bearing wear and reduces the system life. Thicker oil lubricates better, but it also means there is an increase in drag, and more power is needed to rotate the compressor. Manufacturers must consider all these variables when manufacturers designing their equipment. Each new design requires significant testing to ensure performance and energy efficiency.

Finding the right balance of lubricants and refrigerants

May 11, 2021 8:08:00 AM / by Patrick Riley posted in 571 sensor, viscosity management, compressor viscosity, process viscometer

VISCOpro Used in Research to Analyze Viscosity in a Rotary Compressor

Apr 29, 2021 8:31:44 AM / by Patrick Riley posted in 501 sensor, viscosity measuring solution, viscosity control, research, compressor viscosity

When compressor manufacturers design a new compressor model, part of the process includes determining the type of refrigerant and the accompanying lubricating oil, which is necessary to reduce friction on metal parts, reduce wear on the compressor, and extend the life of the system. The company must conduct extensive testing to ensure proper energy efficiency and functionality. The lubricant has a significant impact on the performance of the compressor. Over-lubrication can impact the compressor’s ability to cool properly, but too much refrigerant will lead to more wear and a shorter compressor lifecycle.

Showing Off Our PVT Video Campaign

Apr 21, 2021 6:23:22 PM / by Patrick Riley posted in PVT, high temperature viscometer, high pressure viscometer, 440 sensor

The VISCOlab PVT is a high-pressure, high-temperature viscometer. It is no secret that we are pretty proud of it. The PVT is a great product. It has the widest temperature range, the widest pressure range, and the widest viscosity range of any viscometer on the market. When you want to achieve accurate viscosity measurement under conditions of extreme pressure and temperature, the VISCOlab PVT is your viscometer.

Configuring Your Viscometer When You Know Exactly What You Want

Apr 14, 2021 12:25:40 PM / by Patrick Riley posted in monitor viscosity, viscosity measuring solution, viscosity control, ViscoPro 2100

If there’s anything that we’ve learned in 30+ years of business, it’s that our customers are smart. Often, you’re the best in your field. You know your industry as well as you know the face looking back at you in the mirror.

Reduce blending time for a lubrication product with viscosity analysis

Apr 7, 2021 3:54:45 PM / by Patrick Riley posted in lube oil viscosity, viscosity measuring solution, blending

A refinery was interested in increasing the production of their lubrication products by reducing the time it takes to formulate the products. The facility had several blending tanks in varying sizes, which were used for blending multiple products. Their operating procedures required that they test samples from the top, middle, and bottom of the tanks to ensure the samples were homogenous. Because they didn’t know the exact blending time of the batches, their procedures required that they wait for an hour or more to be sure that full blending had occurred. This effort was time-intensive and could add 45 minutes or more to a batch. If the mixing wasn’t complete and the tests needed to be performed again, even more time would be added to the process.

CVI Offers On-Site Service Capabilities

Mar 24, 2021 9:15:13 AM / by Patrick Riley posted in in-line viscometers, on-site service

- Annual inspection

- Cleaning

- Verification of settings

- Reviewing historical data and error logs

- Calibration verification

Monitor the viscosity of lube oil to reduce failures in engines

Mar 16, 2021 9:43:04 AM / by Patrick Riley posted in lube oil viscosity, viscosity control, viscosity management, 301 sensor

When it comes to rotating equipment, it’s a question of when—not if—a failure will occur. Engine breakdowns, for example, are often caused when the bearings in rotating parts fail. What does this have to do with viscosity, you may be wondering. Faulty bearings can generally be traced to one of three issues: 1) Severe service conditions, 2) improper handling or installation, or 3) poor lubrication.

White Paper: Accurate Viscosity Measurement in Extreme Conditions

Mar 9, 2021 10:39:14 AM / by Patrick Riley posted in PVT, viscosity control, Exploration, high pressure viscometer, EOR

The need for accurate and reliable viscosity measurement in high pressures and temperatures spans many applications across multiple industries. Oil exploration, enhanced oil recovery, and bearing analysis are just a few. Cambridge Viscosity has a long history of meeting these challenges. The key is in the SPL-440 sensor, which is the heart of the VISCOlab PVT. Our new white paper touches on why viscosity measurement is so important when it comes to oil extraction.

Download the White Paper: Achieving Accurate Viscosity Measurement in Conditions of Extreme Pressure and Temperature

Oil condition monitoring for lube oil monitoring on screw compressors

Feb 17, 2021 11:55:02 AM / by Patrick Riley posted in viscosity control, viscosity management, compressor viscosity, in-line viscometers, ViscoPro 2100

Managing lubricant viscosity is essential to maintaining the health of a compressor in a process plant, because a single compressor failure can cost $10,000 a day or more in lost revenue. Considering it’s another $10,000 to rebuild a compressor, or more than $100,000 to replace a compressor, maintaining the health and performance of compressors is important.

Our Top 10 Favorite Questions Relating to Coatings

Feb 10, 2021 12:41:06 PM / by Patrick Riley

When your lab measurements are different than the in-line measurements

Feb 3, 2021 12:39:04 PM / by Patrick Riley posted in viscosity measuring solution, viscosity control, viscosity management, in-line viscometers, ViscoPro 2100, viscometer

There is always some level of uncertainty in comparing on-line viscosity measurements with laboratory measurements. When it comes to viscosity analysis, a major reason for that uncertainty – and inconsistent measurements – is because the fluids are, in fact, under different conditions.

CVI's Viscometers Support the Manufacture of Safety Eyewear

Jan 26, 2021 12:35:09 PM / by Patrick Riley posted in viscosity control, eyewear viscosity, Coating, process viscometer

Safety eyewear has never been more important than right now. In an industry that was already growing at a rate of 4% CAGR, with a projection to reach $3B by 2025, the COVID pandemic created a massive surge in demand for safety eyewear in 2020.

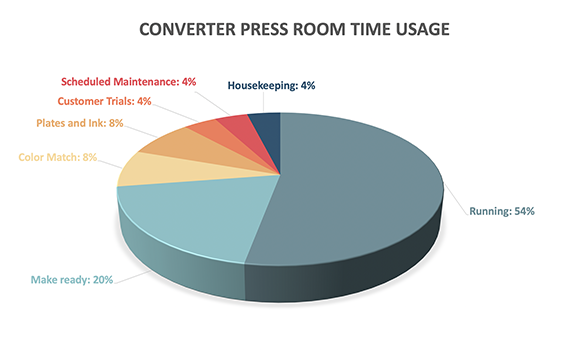

Lessons Learned: Viscosity Control for Converters

Jan 20, 2021 10:08:35 AM / by Patrick Riley posted in viscosity control, coating viscosity, viscosity management, in-line viscometers, process viscometer

Almost two months ago, while those of us in the United States were enjoying our Thanksgiving holiday, our associates in Italy were holding a webinar on viscosity measurement in pressroom converters. This event inspired a series of material discussing the coating application, including last week’s blog highlighting factors that influence viscosity measurement in the pressroom converter application.

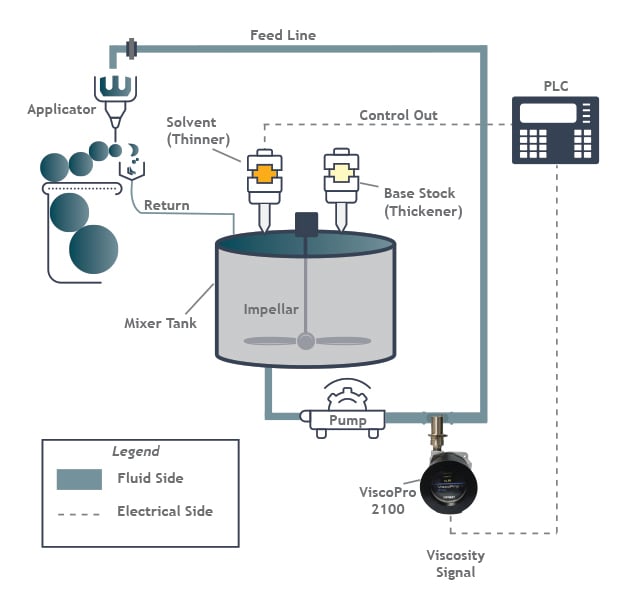

Optimize your converter press room time usage

Jan 14, 2021 3:13:22 PM / by Patrick Riley posted in viscosity measuring solution, coating viscosity, viscosity management, process viscometer

Today's blog discusses pressroom converters. (And we're offering a free white paper on the topic — see the link at the bottom of this post.)

Viscosity Measurement Supports Uniform Coating for Wire Manufacturing

Jan 4, 2021 1:17:06 PM / by Patrick Riley posted in viscosity measuring solution, viscosity control, wire coating, coating viscosity, viscosity management, in-line viscometers, ViscoPro 2100

Spring and wire products are a substantial market – estimated to reach $468B by the end of 2020. Wire is widely used in manufactured goods, including electronics, automobiles, motors, transformers, and a wide array of other products. The coating on the wire is possibly the single most important variable in wire quality, and viscosity plays an important role in ensuring quality.