In shipping vessels, “bunker” refers to the fuel and lube oils that are stored on the ship and used for machinery operation. When the fuel or oil is intended for transfer to another ship for use in its machinery, the operation to transport the oil is called “bunkering.”

There are several grades of bunker fuel, knowns as A, B, and C:

- Bunker A – the most valuable, typically called marine diesel or marine gasoil

- Bunker B - Low-viscosity vac resid range bunker fuel. Often mixed lighter materials to reduce viscosity to the point that it will flow without heating

- Bunker C – The least valuable and most common bunker. Composed primarily of vac resid range material, with a high viscosity that requires heating in order to pump. Sold at several viscosity specifications, including 180 centistoke, 380 centistoke, or 460 centistoke, with 380 being the most common grade.

Currently, most of the global shipping fleet relies on diesel Bunker C fuel oil, and bunker quality can be an issue. To verify bunker quality, vessel operators have traditionally relied on the testing of a sample that can take many days to process. This method has pretty severe limitations. It’s impossible to know if the sample is representative of the entire supply. Bunker fuel is a nonhomogeneous fluid, so how can a tiny sample accurately reflect an amount of liquid that is possibly a million times its size? Doubtful. Also, manually testing a sample can be prone to human error, and getting timely results when they’re needed is a challenge.

Viscosity is an important parameter when it comes to determining the quality of marine fuels. Each grade of bunker is quoted with a specific viscosity tested at 50° Celsius. No matter if a load of bunker is refinery-produced or blended at a shore facility, it is expected to be within a few (cSt) centistokes of its specification. However, in reality, bunker loads can vary considerably from specification and are seldom homogeneous. The causes of off-spec bunkers vary from human error and corruption to instability of blend inherent in the original product. In many cases the supplier is as much a victim of the system as the end-user.

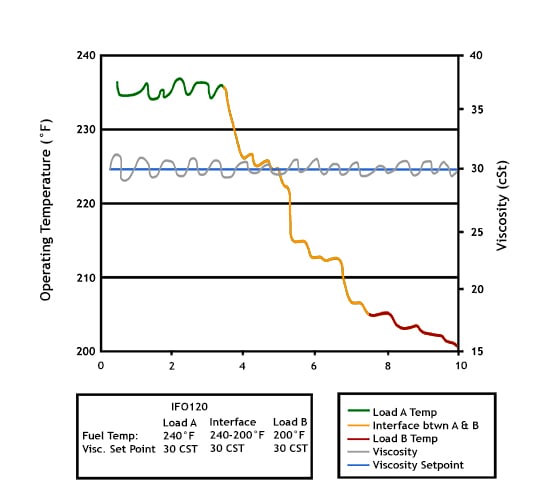

Understanding why the viscosity of blends can vary from load to load is only one piece of the puzzle. Understanding what happens as a result of varying viscosity is another. Varying grades of bunkers form layers when stored in the same storage tank. As a result, in order to maintain a viscosity set point, fuel oil combustion control systems are required to react to drastic changes of bunker viscosity when an interface between varying bunkers meets the fuel oil pump suction. The graph illustrates a considerable change of viscosity between layers of IF0120 referred to in the graph as loads “A" and "B". The change in viscosity required a reduction of fuel temperature from 240° F to 200° F in order to maintain the viscosity set point of 30 cSt. Consider what would happen if the operator relied solely on a theoretical temperature set point derived from typical fuel combustion curves. Burner tips would foul more frequently and emissions would be adversely affected.

Changes in Fuel Oil Temperature Required to Maintain Viscosity Setpoint

Cambridge Viscosity, Inc. offers a solution real-time monitoring of marine bunkers. Our bunker-monitoring version of the VISCOpro 2100 uses an in-line sensor and microprocessor technology to provide real-time viscosity data during bunkering operations. The unique oscillating piston makes our viscometers extremely rugged and insensitive to the harsh marine conditions. With no mechanical linkages and self-cleaning capabilities, the ViscoPro 2100 has virtually no downtime. It can run for years without recalibration. Other features include:

- Viscosity Range: 25-10,000 cP

- Repeatability: 5% of reading

- Temperature Sensor: Up to 375° C

- Pressure Range: 1000 PSI (70 Bar), higher pressures available

- Wetted Parts: Standard 316L/430 Stainless Steel, other materials available upon request

If you’re interested in learning more about the ViscoPro 2100, reach out to our application experts.