Air conditioning systems use refrigerants to do the job of cooling an indoor space. These refrigerants, in the form of hydrochlorofluorocarbons (HCFCs), potentially contribute to climate change, and are currently being phased out of use in the United States. The phaseout approach, which was initially started in 2010, gives manufacturers time to develop ozone-friendly refrigerants as an alternative.

Regulatory Uncertainty Drives Demand for Explosion-Proof Technologies

Jul 14, 2021 1:30:16 PM / by Patrick Riley posted in explosion-proof, viscosity measuring solution, viscosity control, gas compressor, compressor viscosity, refrigerant viscosity

An interview with CVI Rep Suzhou TAIEN about the Compressor Industry

Jun 17, 2021 12:12:25 PM / by Patrick Riley posted in viscosity measuring solution, viscosity control, gas compressor, viscosity management, compressor viscosity

Did you know we have a global representative network that supports Cambridge viscometers all over the world? We decided to reach out to a few of them to get their thoughts on the compressor industry. The first rep we talked to is Suzhou TAIEN, who is responsible for viscometer sales and support in China.

Overview of the 501 Viscometer Sensor

May 25, 2021 1:02:21 PM / by Patrick Riley posted in 501 sensor, viscosity measuring solution

It's no secret to anyone familiar with Cambridge Viscosity that we're proud of our sensor technology. We talk a lot about our oscillating piston technology, which is based on an electromagnetic concept, where two coils move the piston back and forth magnetically at a constant force. (You can see the video showing how it works here.) The patented concept makes for a highly stable, low maintenance viscometer that maintains calibration and needs minimal service. It literally has only one moving part, and no wear points. The most convenient part is that our sensors are self-cleaning.

How to Connect a Lemo Push-Pull Connector

May 20, 2021 11:13:31 AM / by Patrick Riley posted in 501 sensor, viscosity measuring solution

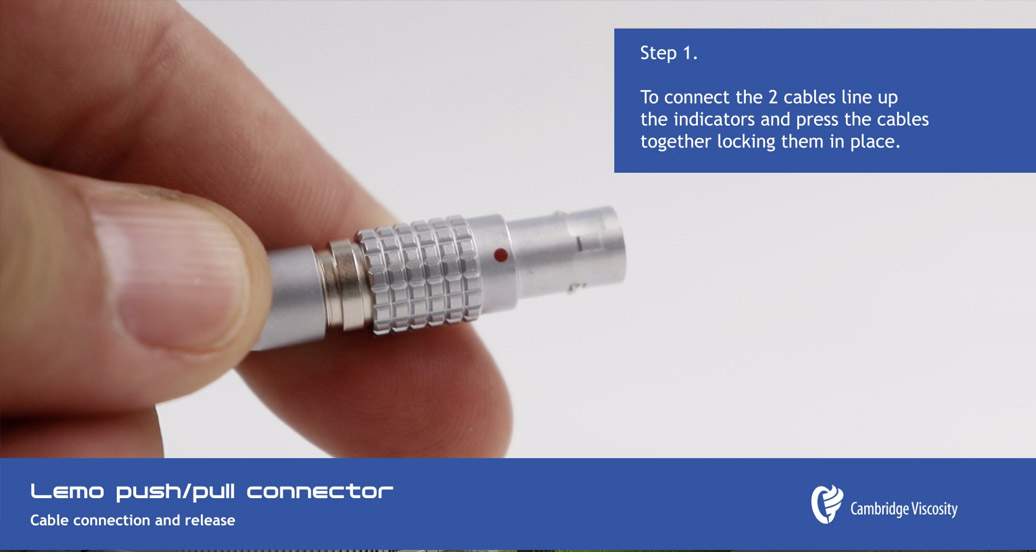

The Cambridge Viscosity 501 viscometer sensor incorporates a Lemo push-pull connector. The Lemo connector is a push/pull style of connector that is self latching. Known to be effective, the Lemo connector is widely used across many industries. The system mates the connectors when the plug is pushed axially into the socket. To do this, line up the red indicator dots and press the cables together, which locks them into place. Once the latch is made, the connection won't release by twisting or pulling any component, other than the outer release sleeve. The connection can only be disengaged by pulling on the outer release sleeve, which allows the user to disengage the latch and withdraw the plug.

To release the cables, grab the knurled release and pull it back. Do not pull the cables apart without using the release, as this can damage both the cable and the sensor.

We've also had a few instances where end-users have twisted the connector, rather than pulled the connector to release. This can also damage the equipment. To better support our customers, we've created the videos below to demonstrate the correct way to release the Lemo connector attached to a CVI 501 Viscometer sensor.

VISCOpro Used in Research to Analyze Viscosity in a Rotary Compressor

Apr 29, 2021 8:31:44 AM / by Patrick Riley posted in 501 sensor, viscosity measuring solution, viscosity control, research, compressor viscosity

When compressor manufacturers design a new compressor model, part of the process includes determining the type of refrigerant and the accompanying lubricating oil, which is necessary to reduce friction on metal parts, reduce wear on the compressor, and extend the life of the system. The company must conduct extensive testing to ensure proper energy efficiency and functionality. The lubricant has a significant impact on the performance of the compressor. Over-lubrication can impact the compressor’s ability to cool properly, but too much refrigerant will lead to more wear and a shorter compressor lifecycle.

Configuring Your Viscometer When You Know Exactly What You Want

Apr 14, 2021 12:25:40 PM / by Patrick Riley posted in monitor viscosity, viscosity measuring solution, viscosity control, ViscoPro 2100

If there’s anything that we’ve learned in 30+ years of business, it’s that our customers are smart. Often, you’re the best in your field. You know your industry as well as you know the face looking back at you in the mirror.

Reduce blending time for a lubrication product with viscosity analysis

Apr 7, 2021 3:54:45 PM / by Patrick Riley posted in lube oil viscosity, viscosity measuring solution, blending

A refinery was interested in increasing the production of their lubrication products by reducing the time it takes to formulate the products. The facility had several blending tanks in varying sizes, which were used for blending multiple products. Their operating procedures required that they test samples from the top, middle, and bottom of the tanks to ensure the samples were homogenous. Because they didn’t know the exact blending time of the batches, their procedures required that they wait for an hour or more to be sure that full blending had occurred. This effort was time-intensive and could add 45 minutes or more to a batch. If the mixing wasn’t complete and the tests needed to be performed again, even more time would be added to the process.

When your lab measurements are different than the in-line measurements

Feb 3, 2021 12:39:04 PM / by Patrick Riley posted in viscosity measuring solution, viscosity control, viscosity management, in-line viscometers, ViscoPro 2100, viscometer

There is always some level of uncertainty in comparing on-line viscosity measurements with laboratory measurements. When it comes to viscosity analysis, a major reason for that uncertainty – and inconsistent measurements – is because the fluids are, in fact, under different conditions.

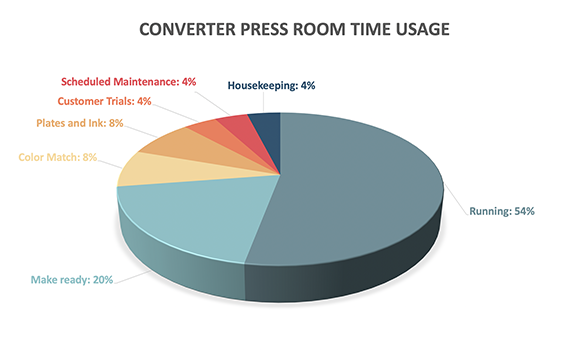

Optimize your converter press room time usage

Jan 14, 2021 3:13:22 PM / by Patrick Riley posted in viscosity measuring solution, coating viscosity, viscosity management, process viscometer

Today's blog discusses pressroom converters. (And we're offering a free white paper on the topic — see the link at the bottom of this post.)

Viscosity Measurement Supports Uniform Coating for Wire Manufacturing

Jan 4, 2021 1:17:06 PM / by Patrick Riley posted in viscosity measuring solution, viscosity control, wire coating, coating viscosity, viscosity management, in-line viscometers, ViscoPro 2100

Spring and wire products are a substantial market – estimated to reach $468B by the end of 2020. Wire is widely used in manufactured goods, including electronics, automobiles, motors, transformers, and a wide array of other products. The coating on the wire is possibly the single most important variable in wire quality, and viscosity plays an important role in ensuring quality.

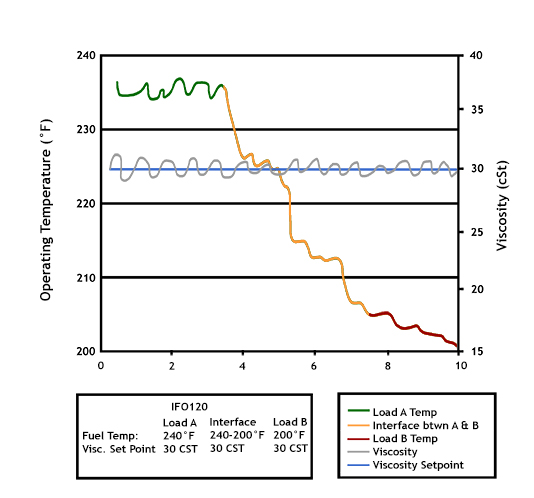

Determining the Viscosity of Heavy Fuel Oils

Dec 8, 2020 3:44:17 PM / by Patrick Riley posted in viscosity measuring solution, viscosity control, heavy fuel oil viscosity, viscosity management, in-line viscometers

In shipping vessels, “bunker” refers to the fuel and lube oils that are stored on the ship and used for machinery operation. When the fuel or oil is intended for transfer to another ship for use in its machinery, the operation to transport the oil is called “bunkering.”

Optimize coating applications through tighter viscosity control

Dec 2, 2020 9:07:18 AM / by Patrick Riley posted in viscosity measuring solution, viscosity control, coating viscosity, viscosity management, Coating, ViscoPro 2100

When it comes to coatings, product quality can live or die by viscosity. A too-viscous mixture can result in bubbling and an inconsistent, bumpy, “orange-peel” texture. A solution that is not viscous enough can result in a coating that is too thin, drippy, or saggy. Plus, depending on the application, a coating that is too thin may not provide the necessary top-coat protection. In either case, a coating that has an off-spec viscosity in either direction can result in product rejection or product failure.

CVI Supports R&D for the Use of Nanoparticles in Heat Transfer Fluids

Nov 11, 2020 4:08:10 PM / by Patrick Riley posted in viscosity measuring solution, viscosity control, viscosity management, viscometer support

It’s always interesting to see how our customers use the Cambridge Viscosity viscometers to support product development and continuous improvement. Our customers monitor viscosity in thousands of unique applications – they develop pharmaceuticals that improve quality of life, they test engine oils to make sure cars and airplanes operate more efficiently and heavy marine fuel so shipping companies to achieve proper fuel efficiency. They monitor the viscosity of coatings, to create high-quality lenses of all types. And, in the oil and gas industries, our viscometers provide the data necessary to understand the makeup of the raw material, so it can be handled and processed appropriately.

Viscosity Measurement Helps to Overcome Manufacturing Challenges

Oct 21, 2020 6:00:00 AM / by Patrick Riley posted in viscosity measuring solution, viscosity control

Quality control and the ability to meet the demand for rapidly changing technologies are big challenges for electronic components manufacturers. Parts like capacitors – which can be as small as the head of a pin in certain applications – must meet critical performance targets. Cambridge Viscosity helped a U.S.-based manufacturer overcome one of its manufacturing challenges. The company wanted to use a paste to apply dielectric material with highly precise characteristics in a paste form onto a capacitor substrate, which had a significant impact on the final product characteristics.

How to Field Calibrate Your Viscometer

Aug 12, 2020 8:00:00 AM / by Patrick Riley posted in process viscometers, viscosity measuring solution, viscosity management, in-line viscometers, viscosity

Comparing on-line viscosity measurements to the lab is challenging. Process conditions can change, laboratory samples can off-gas, fluids may be non-Newtonian and measure