November in New England, where Cambridge Viscosity is headquartered, is the time of year when our leaves finish falling and the weather turns cold. Soon, it will be snowy and frigid in Massachusetts. (Who are we kidding – we had our first snowfall in October this year!) Inspired by the chill in the air, we thought we’d talk about some of the challenges of measuring viscosity in colder atmospheric conditions, where ambient temperatures fall below 50 °F for part of the year

Measuring viscosity in asphalt leads to a reduction in energy usage

Nov 17, 2020 2:59:47 PM / by Patrick Riley posted in viscosity control, asphalt viscosity, ViscoPro 2100, process viscometer

CASE STUDY: Using Viscosity Measurement to Achieve Consistent Coatings

Sep 2, 2020 1:29:00 PM / by Patrick Riley posted in coating viscosity, ViscoPro 2100, Glass coating viscosity, thin film coating, madico

Monitoring the viscosity of coating products to achieve higher product quality and reduce maintenance downtime

CHALLENGE

Controlling the viscosity of coating products is a significant challenge for manufacturers across a wide range of applications, from optical and medical to drum coating. The fluids are often difficult to work with and must be formulated and used within strict parameters to achieve the desired film weight, thickness, and image characteristics.

How to Configure my Viscometer

Aug 5, 2020 8:08:45 AM / by Patrick Riley posted in ViscoPro 2100, viscometer

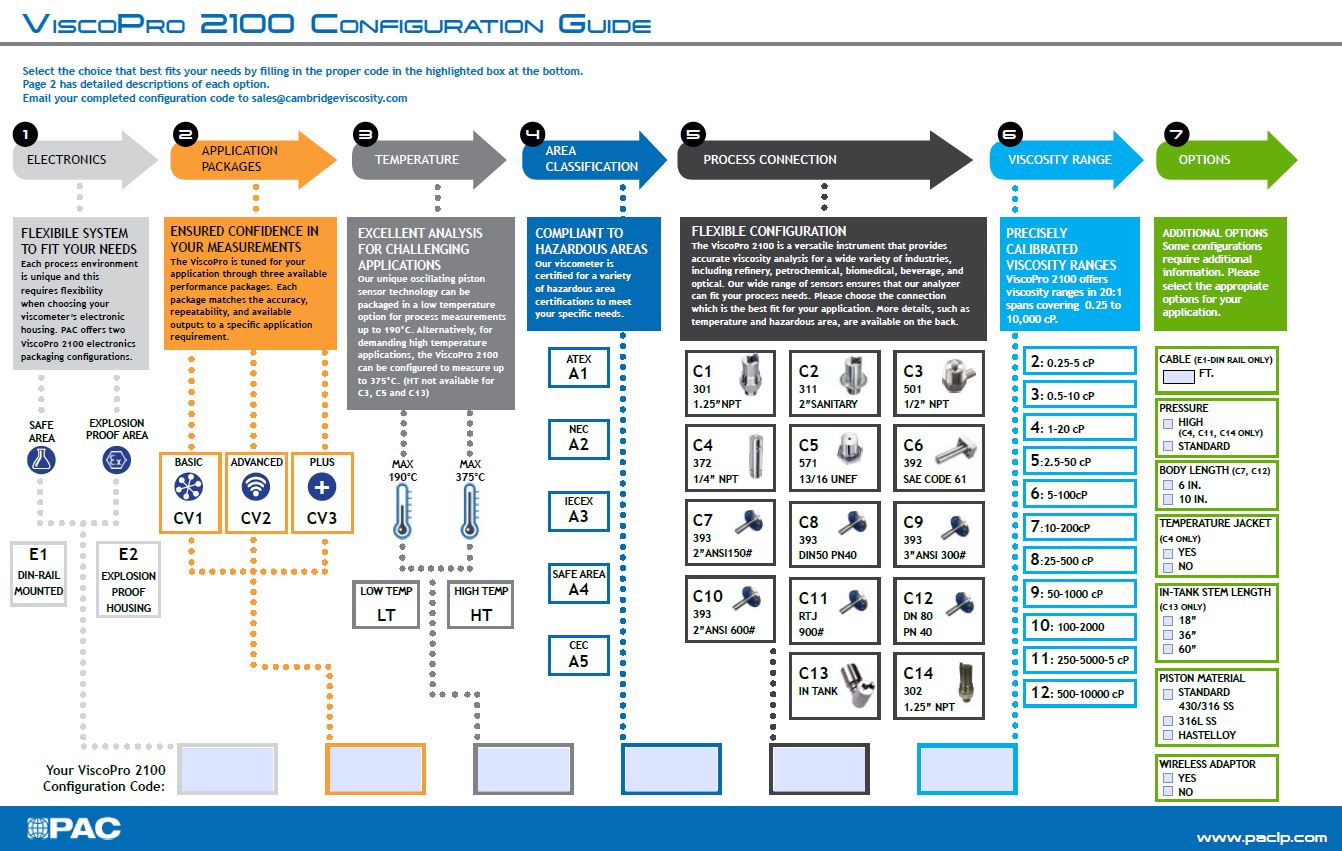

The Viscometer Configuration Guide is used to build our viscometer to meet your unique process needs. Our VISCOpro 2100 platform offers a range of options for different mounting, outputs, and sensors choices. The guide steps you through choosing these options and builds a specific product code which can be used for specifications, pricing, drawings, and literature.

New Rugged Viscometer Withstands Harsh EOR Conditions

Nov 20, 2019 8:00:00 AM / by Admin posted in VISCOpro2000, process viscometers, 393 sensor, Exploration, EOR, ViscoPro 2100

Boston—Cambridge Viscosity has developed a rugged, RTJ-flanged in-line process viscometer for a leading global oil company’s Enhanced Oil Recovery (EOR) application in the North Sea. Cambridge designed the SPL-393 viscometer for use offshore, where safety and reliability are not just a priority but also a necessity. The new viscometer meets all electrical, plumbing material, pressure and temperature requirements for use on a platform where environmental conditions can reach extremes.

The sensor connects into a pipeline using a standard ANSI class 900/1500 2" RTJ round flange. The rugged 316SS construction can withstand up to 2200 PSI and 190 degrees C, and has long penetration for large diameter pipes. The SPL 393 satisfies ASME PTC 19.3 Thermowells requirements. The new sensor is designed for highly accurate, repeatable viscosity readings and clean-in-place simplicity. Coupled with Cambridge's standard VISCOPro 2000 or ViscoPro 2100 electronics, the sensor has sophisticated multi-shear compatibilities.

Cambridge Director of Engineering Dan Airey says, "We are very excited to introduce this product designed to meet the specific needs of the petroleum industry. The initial application of the SPL-393 sensor in EOR oil production improves production efficiency while withstanding harsh offshore drilling conditions. Our customer is achieving repeatable, reliable viscosity measurements that contribute to better control of EOR operations.”

About Cambridge Viscosity

Cambridge Viscosity, a leader in small sample viscometer systems for laboratory and process environments, designs automated viscometers used worldwide in petroleum, exploration and refining applications to ensure accurate viscosity in both lab and operations. Cambridge’s worldwide reach is important for providing application engineering support and service wherever and whenever needed.

Cambridge Viscosity’s sensors and viscometer systems conform to ASTM, DIN, JIS and ISO standards, with a range of models designed to meet specific industry and application needs.

To learn more visit www.cambridgeviscosity.com.