Estimating potential savings is one thing; achieving them is something else. Industry consultant Don Wren talked about his experience at Doublecote. “After years of measuring viscosity with an off-line unit and being dissatisfied with the results as well as the high level of maintenance it required, Doublecote looked for an in-line unit that would be not only scientifically accurate but also highly reliable,” Don indicated. He went on to say, “in our testing, Cambridge’s VISCOpro viscometers stood head and shoulders above the rest. Not only are the Cambridge viscometers small, accurate, and reliable, but they automatically clean themselves during normal operation. This gave us to payback the cost of the viscometers and their installation in about a third of the first year.”

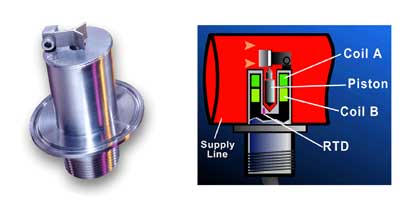

Measurements are performed using only one moving part (the piston) that does not require any seals or mechanical linkage. All wetted materials are constructed of Stainless Steel. The fluid sample is constantly updated and new measurements are reported every few seconds. The “Constant-Clean” feature instructs the piston to move throughout the chamber to keep any material from building up. The combination of a continuously refreshed sample, a rugged design and self-scrubbing motion of the piston provide for extremely accurate and virtually maintenance-free operation in many environments.

Figure 2:Cambridge Viscosity Electromagnetic In-line Sensor

Measurements are performed using only one moving part (the piston) that does not require any seals or mechanical linkage. All wetted materials are constructed of Stainless Steel. The fluid sample is constantly updated and new measurements are reported every few seconds. The “Constant-Clean” feature instructs the piston to move throughout the chamber to keep any material from building up. The combination of a continuously refreshed sample, a rugged design and self-scrubbing motion of the piston provide for extremely accurate and virtually maintenance-free operation in many environments.

Don indicated that “as soon as the Cambridge units were installed, Doublecote began realizing significant cost savings and quality improvements.”

For more information about viscosity control and how it can help at your facility, email info@cambridgeviscosity.com or call 781 393-6500.

<< 1 | 2 >>

“In our testing, Cambridge's VISCOpro viscometers stood head and shoulders above the rest. Not only are the Cambridge viscometers small, accurate, and reliable, but they automatically clean themselves during normal operation.”

- Don Wren, industry consultant, speaking about his experience at Doublecote.

Known for innovation in viscosity measurement and control, Cambridge Viscosity specializes in the industry's most accurate, reliable, and easy-to-use viscometers for research laboratories and process environments.

Cambridge Viscosity, Inc.

50 Redfield St, Suite 204

Boston, MA 02122 USA

781 393-6500

Email: Sales@CambridgeViscosity.com