In-Line Viscometer for the Process Industry

Cambridge Viscosity’s ViscoPro 2100 is designed to stand up to the challenges within the process industry. With a sensor that is designed to protect itself from outside elements, the ViscoPro 2100 is highly insensitive to the outside environment. Its continuous piston motion means that the VP2100 is self-cleaning and can run for years without recalibration.

Viscosity Range: 0.2-10,000 cP

Repeatability: 0.5% of reading

Temperature Sensor: Up to 375° C

Pressure Range: 1000 PSI (70 Bar), higher pressures available

Wetted Parts: Standard 316L/430 Stainless Steel, other materials available upon request

| Specifications | |

| Viscosity Range | 0.2-10,000 cP, 11 Ranges in 20:1 spans |

| Accuracy | 1% |

| Repeatability | CVI: 1.5% of reading CV2: 0.5% of reading |

| Temperature Sensor | PT100 |

| Input Power | 24 VDC, all models |

| Display | Embedded bright OLED display Viscosity, Temperature, Temperature-Compensated Viscosity, Quality Indicator |

| Electronics Ambient Temperature Range | Up to 60° C |

| Certifications | E1 Models: Safe Area E2 Models: Class 1, Div 1, Group B, C, C; Class 1 Zone 1, AEx d IIB+H2 Class 1 Zone 1, Ex d IIB+H2 cFM, FM, Ex, IECeX, and CE |

| Analog Output | CV1 (2) 4-20mA outputs (500 ohm max loop resistance) CV2/CV3 (3) 4-20mA out |

| Digital Outputs | CV1 None CV2/CV3 RS485 Modbus RTU (Full Duplex) |

| Maximum Process Temperature Rating | C1, C2, C3, C4, C5, C6 up to 1000 psi C7 up to 200 psi (393-2" ANSI 150#) C8 up to 600 psi (393 DN50 PN40) C9 up to 375 psi (393- 3" ANSI 300#) C10 up to 700 psi (393- 2" ANSI 600#) C11 up to 1,000 psi (2" RTJ 900#) |

| Dimensions | DIN 3.3" 9 (h) x 7.1" (2) x 4" (d), 34mm (h) x 180mm (w) x 100mm (d) Ex (w/o sensor) 4.5" (w) x 4.8" (h) x 5.7 (d) |

| Power | 24VDC (15W max) |

| Alarm Output | 190mA open collector (3V-50VDC) |

| Weight | DIN 3lb 1.4kg Ex 4lb 1.8kg |

| Wetted Components | Standard 316L/430 Stainless Steel, other materials available upon request |

| Options | 140-0018 DIN rail mount - Power Supply, 100-240VAC to 24VDC, IEC 60W Class 1 Div 2 803-21 VISCOpro 2100 Wireless Router Assembly Kit |

When measuring the flow of products within a process environment, conditions are often severe—vibration, flow, and varying pressures can impact instrument readings. ViscoPro 2100 features a rugged design to stand up to the challenges within the process industry. With a small sample size, easy installation, flexible configuration, and minimal maintenance needs, the ViscoPro 2100 is the ideal viscosity transmitter for almost any refinery, petrochemical, or coatings application.

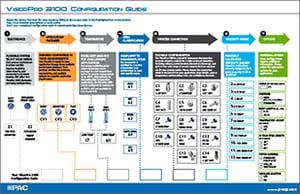

To make it easy to order the viscometer that is best for you, we created a seven-step configuration guide. We have a blog post with detailed instructions. Simply select the viscometer that best fits your needs by filling in the proper code in the highlighted box at the bottom of the page.

Known for innovation in viscosity measurement and control, Cambridge Viscosity specializes in the industry's most accurate, reliable, and easy-to-use viscometers for research laboratories and process environments.

Cambridge Viscosity, Inc.

50 Redfield St, Suite 204

Boston, MA 02122 USA

781 393-6500

Email: Sales@CambridgeViscosity.com