Viscosity Range: 0.5 to 500 centipoise (cP)

Repeatability: ± 0.8% of Reading

Accuracy: ± 1.0%

Temperature Range: 375°F (190°C)

Pressure Range: 1,000 psi (70.3 bar)

Wetted Parts: 316L and 430 Stainless Steel

| Specifications | |

| Viscosity | 0.5 to 500 centipoise (cP) |

| Piston Ranges | 0.5-10cP, 1-20cP, 2.5-50cP,* 5-100cP, 10-200cP, 25-500cP* *requires VISCOpro 2000 electronics |

| Viscosity Accuracy | ± 1.0% of Full Scale |

| Repeatability | ± 0.8% of Reading |

| Temperature Sensor | 4 wire internal RTD |

| Wetted Materials | 316L and 430 Stainless Steel |

| Maximum Particle Size | 25-100 microns (Range Dependent) |

| Max Ambient Temperature | 375°F (190°C) |

| Max Operating Pressure | 1,000 psi (70.3 bar) |

• Multiple ranges (one piston per range)

• Additional cable

• High pressure system (also available)

The SPL 571 OILSENSE™ is used extensively for compressor, used oil analysis, on-engine and hydraulic fluid applications. It is ideal for installations where form factor and small sample volume are important.

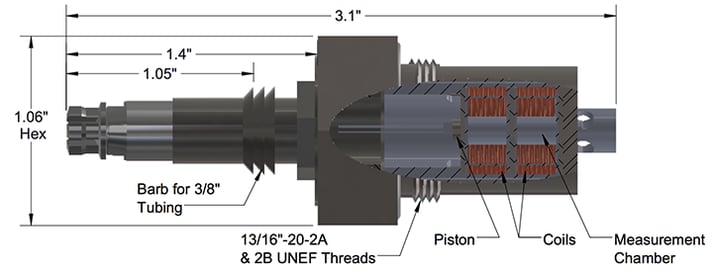

Our viscosity management technology is based on a simple and reliable electromagnetic concept. Two coils move the piston back and forth magnetically at a constant force. Proprietary circuitry analyzes the piston’s two-way travel time to measure absolute viscosity.

A built-in temperature detector (RTD) senses the actual temperature in the sampling chamber. Constant in and out motion keeps samples fresh, mechanically scrubs the sampling area and provides excellent viscosity tracking.

The SPL571 OILSENSE installs neatly into a 1/2” block fitting or tee. Measurements can be made in any of 6 different 20:1 viscosity ranges between 0.5 and 500 centipoise (cP). Recommended fluid flow over the sensor is up to 1.0 ft/sec.

Known for innovation in viscosity measurement and control, Cambridge Viscosity specializes in the industry's most accurate, reliable, and easy-to-use viscometers for research laboratories and process environments.

Cambridge Viscosity, Inc.

50 Redfield St, Suite 204

Boston, MA 02122 USA

781 393-6500

Email: Sales@CambridgeViscosity.com