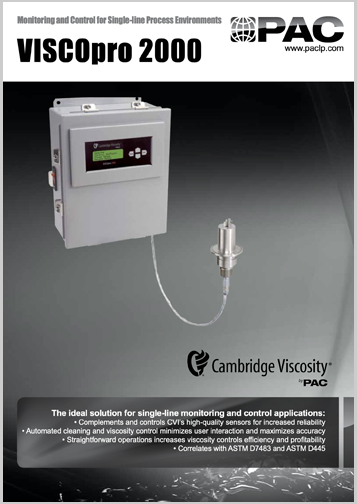

Online Viscosity Controller for Process Industries

Ideal for single-line monitoring and control applications, the ViscoPro 2000 combines powerful electronics with our innovative sensor technology in a single automated viscometer. The ViscoPro 2000 offers automated fluid monitoring for continuous, reliable, accurate viscosity measurement.

Viscosity Range: 0.2-20,000cP

Accuracy: 1%

Repeatability: 0.8%

Maximum Temperature: Up to 375°C (sensor)

Maximum Operating Pressure: Up to 5000 psi (sensor)

Wetted Components: Standard 316L, 430 Stainless Steel, and other alloys available

| Specifications | |

| Outputs | 100-240 VAC, 12 VDC, 24 VDC, 12 W |

| Repeatability | 4 4-20mA; 1 RS232 (standard)/RS485 (optional); 1 5V-TTL alarm; 1 on-off port for alarm or control |

| Accuracy | ± 1.0% of full scale (correlates to ASTM D445) |

| Repeatability | 0.8% |

| Ranges | 0.2-20,000cP (0.2-2cP, 0.25-5cP, 0.5-10cP, 1-20cP, 2.5-50cP, 5-100cP, 10-200cP, 25-500cP, 50-1,000cP, 100-2,000cP, 250-5,000cP, 500-10,000cP, 1,000-20,000cP) |

| Wetted components | Standard 316L/430 Stainless Steel Optional: Hastelloy and Sanitary Components |

| Maximum temperature | 190°C (sensor); 60°C (display electronics) |

| Maximum standard operating pressure | 1000 psi (70.3 bar) |

| Optional operating pressure | 2000psi (140.2 bar) |

| Temperature sensor type | 4 wire Platinum RTD |

| Certifications | FM, 3A, CE, ATEX - EExdlllC (300 series sensor only) [EEx d IIC T4, -20C<Ta<95C (For SPL Models), EEx d IIC T2, -20C<Ta<190C (For SPL Models)] Factory Mutual - Class 1 Div.1, Group C, D:T3 NEMA4,IP-66 |

With the ViscoPro 2000 viscometer, menu-driven electronics drive and interpret Cambridge Viscosity’s high-quality in-line and in-tank sensors. Powerful yet easy to use, the ViscoPro 2000 provides viscosity, temperature, temperature-compensated viscosity, and optional density readings on an enhanced visual display panel. Thirteen factory-set standard measurement ranges from 0.2-20,000 cP are available for greater accuracy and process viscosity control.

An intuitive menu allows users to select operating characteristics and control set points and alarms with six different settings.

Features include:

Download our comparison chart to determine which process viscometer is the best option for your needs.

Known for innovation in viscosity measurement and control, Cambridge Viscosity specializes in the industry's most accurate, reliable, and easy-to-use viscometers for research laboratories and process environments.

Cambridge Viscosity, Inc.

50 Redfield St, Suite 204

Boston, MA 02122 USA

781 393-6500

Email: Sales@CambridgeViscosity.com